CIMT 2021

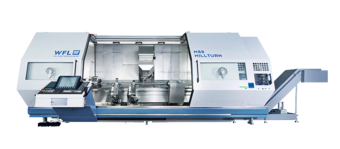

At CIMT 2021 the highlight of the show is the presentation of the M50 MILLTURN and the new generation of this machine with a bigger centre distance and increased performance.

At CIMT 2021 the highlight of the show is the presentation of the M50 MILLTURN and the new generation of this machine with a bigger centre distance and increased performance. The innovative and optional 6000mm centre distance enables WFL to offer efficient options for the machining of long and lean shaft parts. The special emphasis of the product presentation lies on the maximum machine performance.

There are innovations in the segment for machine sizes with a turning diameter of up to 670 mm: alongside the additional 6000 mm centre distance option, the fully developed, tried-and-tested M50 MILLTURN basic machine concept will also be provided with an optical and ergonomic finish.

The focus lies on the machine’s new design, which incorporates spin windows that are 50% larger and a horizontal magazine window that is extremely easy to handle. For the first time, the option for an M50-G MILLTURN with a counter spindle is also available. In combination with a tool turret or a further machining unit, work can be performed on both main spindles at the same time. Both machine options are available with the following centre distances: 1000 mm, 2000 mm, 3000 mm, 4500 mm and 6000 mm.

There is a separate pick-up magazine for very long and/or heavy tools. Work pieces with a length up to 1600mm can be used and changed automatically. Even though the disc magazine can be enhanced up to 200 stations recently, all tool stations can still be accessed directly. Furthermore, new and particularly reliable optical sensors have been installed within the tool magazine for monitoring the tool stations.

With the fundamental new development of the in-house process monitoring, WFL has significantly expanded the range of functions. With the new “WFL iControl” system, process signals can be registered, evaluated and recorded in the CNC-kernel of the control with the highest sampling rate. The introduction of new monitoring strategies, such as so-called “yellow limits”, results in considerable advantages in tool breakage and tool wear monitoring. Another new feature is the option of integrating external sensors into process monitoring. The latter allows, for example, continuous monitoring and recording of performance data from coolant pumps or conclusions about the condition of spindle bearings.

With the new “iControl” process monitoring system, WFL gives the future machine operator a whole bundle of functions to ensure reliable and economical production, particularly in series production. On the one hand, the machine and tools should be used with maximum productivity; on the other hand, the process should run as stable and reliably as possible. The software package that WFL provides for this is extremely diverse and offers a suitable monitoring tool for practically every processing situation. The up to 16 process signals to be monitored are configured by WFL at the factory according to the machine equipment and displayed live on the control screen. Important process signals are the forces or torques of the NC axes and spindles, but also the signals from integrated sensors (vibration, pressure, flow, temperature, etc.), built into machine components or in sensory tools, can be used for a wide variety of applications. E.g. for process control, optimization or monitoring. As with many areas of daily life, the following applies here: once you’ve tried it, you don’t want to go without it.

How about your exhibits and the applications in some industries, i.e. Aerospace or Autombile, etc, and how about the effect with your products or technologies?

We have been building complete machining centres for various well-known customers in the aviation, engineering and plastics machinery industries, among others. The aerospace industry represents an important market segment for us. More and more materials, which are hard to machine are becoming prevalent in this sector. The most important requirement our products must satisfy is absolute process reliability.

Landing gear, turbine shafts, fuel pump housings and other aerospace components require technological solutions that have been specially adapted. The objective here is to ensure that machining is economical. Therefore, the advantages of complete machining are particularly illustrated in this sector. Thanks to the broad technological spectrum of the multifunctional turning-boring-milling centres and decades of experience, our customers can rely on the highest levels of productivity.

Time-saving programming solutions combined with precise milling enable highly efficient production of screw shapes on a MILLTURN. In addition, sophisticated deep hole drilling solutions give our machines a decisive advantage in comparison with conventional production methods.

The manufacturing of key components for high-tech engineering is in a class of its own – the highest level of productivity for roughing and finishing without grinding whilst maintaining the narrowest of tolerances, together with integrated workpiece measurement are among the requirements. Alongside technological factors, process-safe manufacturing and a high level of flexibility of the machine design also play a very important role. Our MILLTURNs master these challenges with ease.

What are your company’s main new technologies and products in CIMT? What are the core competitive advantages of these technologies and products? Please briefly introduce them .

The latest product in our portfolio is the M20 MILLTURN. When developing the M20, the objective was to introduce a compact and rigid machine designed for long-term accuracy.

The machine frame is made from spheroidal graphite, which is extremely strong and guarantees excellent damping characteristics. Thanks to the construction of the machine, which incorporates vibration-absorbent cast components that offer optimum rigidity, even the heavy cuts that are required during machining are carried out without vibration. Large spaces between the guide rails and trolleys on the slide guides also guarantee a high degree of system rigidity.

We also wanted that the configuration of the machine to allow for a wide range of possibilities: from a pure complete machining centre with steady rest and tailstock, as a counter spindle machine with tool turret or an individual tool holder at the bottom, as well as an optional integrated workpiece handling system.

Furthermore, the new process control software WFL iControl protects the MILLTURN, even during autonomous production throughout the night. Depending on the machine‘s equipment, up to 16 freely configurable process signals are continuously monitored. The new design contains more complex and more intelligent monitoring options, offering comprehensive safety during production. Multi-stage monitoring logics are used, which respond, if the collision limit or adaptive process limit is exceeded, or if there are significant, rapid changes in force.

What are your expectations for CIMT 2021?

By participating in CIMT 2021 we expect to connect with potential customers, other target groups and prospective buyers. The regional market in China is very interested in this event and a specialized audience will be present. Even in times of the current pandemic and increased digital communication, we value the opportunities of personal contact with our customers, especially when they live on the other side of the planet. The exhibition show appearance at the CIMT in Beijing is an anchor point for a variety of communication activities. For our company it is important that an exhibition appeals to all the senses that a website, a sales letter or an advertisement cannot afford. That is why we can convey outstanding aspects of new customer communication and customer loyalty, such as reliability, trust, personal appreciation, meeting individual requirements, dialogue orientation etc.

In the face of the uncertainty of external environment changes, in your opinion, how should enterprises plan their own future development and achieve the original development goals?

At WFL, we have continued to act according to the motto “best in complete machining” and offer our customers the most efficient manufacturing solutions, high-quality machines and the highest quality of service.

Despite the difficult times, we produced many innovations and further developments in the course of 2020. Throughout the year, despite the constant presence of COVID, our MILLTURNs were shipped worldwide, assembled in the respective country and put into operation. In summary, one can say that we got through the crisis well. We owe this above all to the special commitment of all employees at home and abroad during this difficult phase.

Our target for 2021 is to grow faster than the market. We intend to do this with outstanding products from machines to software and from production solutions to customer services. We want to have a stronger presence in the markets, establish additional branches and look after national regions. We want to use the latest technology, not just in its machines but also in its processes and service support.

Due to the influence of various aspects in 2020, enterprises will have more emphasis when choosing exhibitions. So what is the reason that 2021 CIMT attracts your company to participate in? What are your core development concepts and innovative solutions that you hope to present to the industry through this exhibition?

CIMT is the the most important exhibition for us in the Chinese market. Also, for us, China remains among the leading countries in terms of sales. With our development as a total solution provider, we are in a position to provide our customers with comprehensive and sustainable support over the entire life cycle of a MILLTURN. We can also offer many great solutions around the topic of Industry 4.0 or digitization: starting with the updated version of CrashGuard Studio, the completely new process monitoring WFL iControl and further developments in sensor technology in tools and the MILLTURN, we prove strong progress.

Interviewee: Günther Mayr, Managing Director Sales and Technologies I Interviewer: MM China