Operational data acquisition system with myWFL

With the new myWFL operational data acquisition system, you can maintain an overview around the clock and exploit the optimisation potential for the smart factory. The new software not only has a user-transparent display, but also improves machine utilisation. All data in the production environment is collected and analysed to achieve higher productivity. Shorter production times and a more effective design of the Smart Factory processes thus go hand in hand.

In furthering the smart networking and digitalization of the production, WFL is presenting a new, interesting software so- lution for operational data acquisition. The new product range, myWFL, consists of the operational data acquisition software myWFL Cockpit, the multifunctional energy optimisation tool myWFL Energy and the myWFL Condition Monitoring System.

Advantage

- 24/7 overview

- Exploiting of optimisation potential of the Smart Factory

- Transparent user interface

- Improvement of machine utilisation

- Collection and analyses of all data from the production environment with the aim of increasing productivity

- Shorter production times and more effective organisation of smart factory processes

myWFL Cockpit

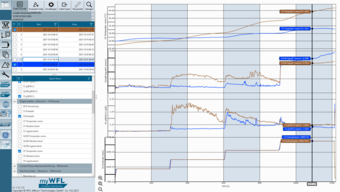

myWFL Cockpit is an operational data acquisition system that displays the machine state (e.g. productive, available or malfunction), performance (productivity and availability), modes of operation and override settings over time.

Display of:

- Operating hours

- Channel status

- Active NC program

- Active tool

- Program runtime

- Machine productivity (OEE) and technical availability in a definable observation period

Other features:

- Data is collected and stored locally on the control system (not cloud solution)

- Data can be viewed on the control system display.

- Dashboards are also offered via a web interface via the internal customer network and can therefore also be viewed on the workstation PC or on mobile devices (tablets, mobile phones) via a web browser

- Automatic adaption of the software to different window formats and resolutions

myWFL Energy

myWFL Energy is a possible extension of myWFL Cockpit with a multifunction energy consumption meter for the power and compressed air consumption of the entire machine. This allows the current power and energy con- sumption data to be determined and displayed over time as well as the energy consumption per workpiece, e.g. for a comparative view of the total energy consumption between different machining technologies.

Features:

- Display of electrical characteristic values such as voltage, amperage, apparent, active and reactive power, power factor, frequency, min/max values, active and reactive energy

- Recording and display of energy consumption and switch-on times of various units such as the high- pressure coolant pump per workpiece or per NC program run

myWFL Condition Monitoring

The integrated condition monitoring cycle is used to ensu- re comparable processes, such as traversing the working area in all main axes as well as specific speed profiles of the spindles.

Features:

- Continuous recording and storing of friction values of the axes and spindles when cycle is running

- Recording of temperature in the milling spindle housing and vibration or rolling bearing condition value of the front milling spindle bearing and storing on the control system

- Condition Monitoring Viewer: possibility of recording the friction and other sensor data and possibility of a comparative display of this data for different runs. This makes it possible to visually check whether, for example, significant changes between the new condition and the current condition are apparent or not