M200 MILLTURN

The giant

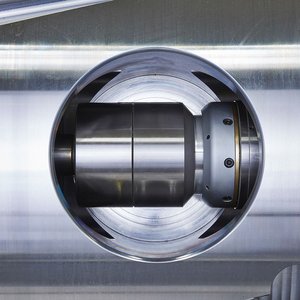

Designed by the Austrian high tech company WFL Millturn Technologies, the M200 MILLTURN is a first-class multifunctional turning-boring-milling center. Complete machining enters a whole new dimension with this revolutionary machine-tool generation.

Established MILLTURN-assemblies were combined with a new machine bed concept in order to create an uncompromising turning-boring-milling center for complete machining of large work pieces. Different headstock and tailstock versions cover operations ranging from the production of aerospace components with large swing diameters to the production of large and heavy chuck or shaft parts.

Highlights auf einen Blick

- UHPC with up to 350 bar

- Tool change in any Z-axis position

- Standard disc-type magazine with up to 90 tool stations

- Heavy boring bar magazine

M200 | ||

|---|---|---|

| Nominal center distance | mm | 5000/6500/8000/10000/12000/14000/* |

| Swing - ø over Top slide | mm | 2000 |

| Max. Turning- ø between centers | mm | 2000 |

| Max. power, Turning spindle 100% duty cycle | kW | 100/140/180 |

| Max. torque, Turning spindle 100% duty cycle | Nm | 9800/40000/87000 |

| Max. spindle speed, Turning spindle | min-1 | 1000/500/350 |

| Max. power, Miling spindle 100% duty cycle | kW | 80 |

| Max. torque, Milling spindle 100% duty cycle | Nm | 1800 |

| Max. spindle speed, Milling spindle | min-1 | 3500 |

| Swiveling angle B - axis | degree | 220(-110...+110) |

| Travel Y - axis | mm | 1400(-800...+600) |

| Travel X - axis | mm | 2100(-20...+2080) |

Tailstock, quill - ø | mm | 300/500 |

| Tool magazine | number | 30/60/90/* |

| Control SIEMENS | type | SINUMERIK ONE |

Tool magazine

Tool change

- Generously dimensioned and automated tool changer with double gripper

- Time-saving due to a highly dynamic changing sequence

- Reliable changing sequences, also with heavy tool weights

- Tool change in any Z-axis position

- Tool change of tools measuring up to 1000 mm and 40 kg possible

Tool magazine

- Standard disc-type magazine with up to 90 tool stations

- Optional chain magazine for operations involving a high number of tools

- Optional magazine version for particularly long and heavy tools (e.g. heavy boring bars)

- Optimum user-friendliness of all magazine versions