M50, M50-G MILLTURN

The power pack

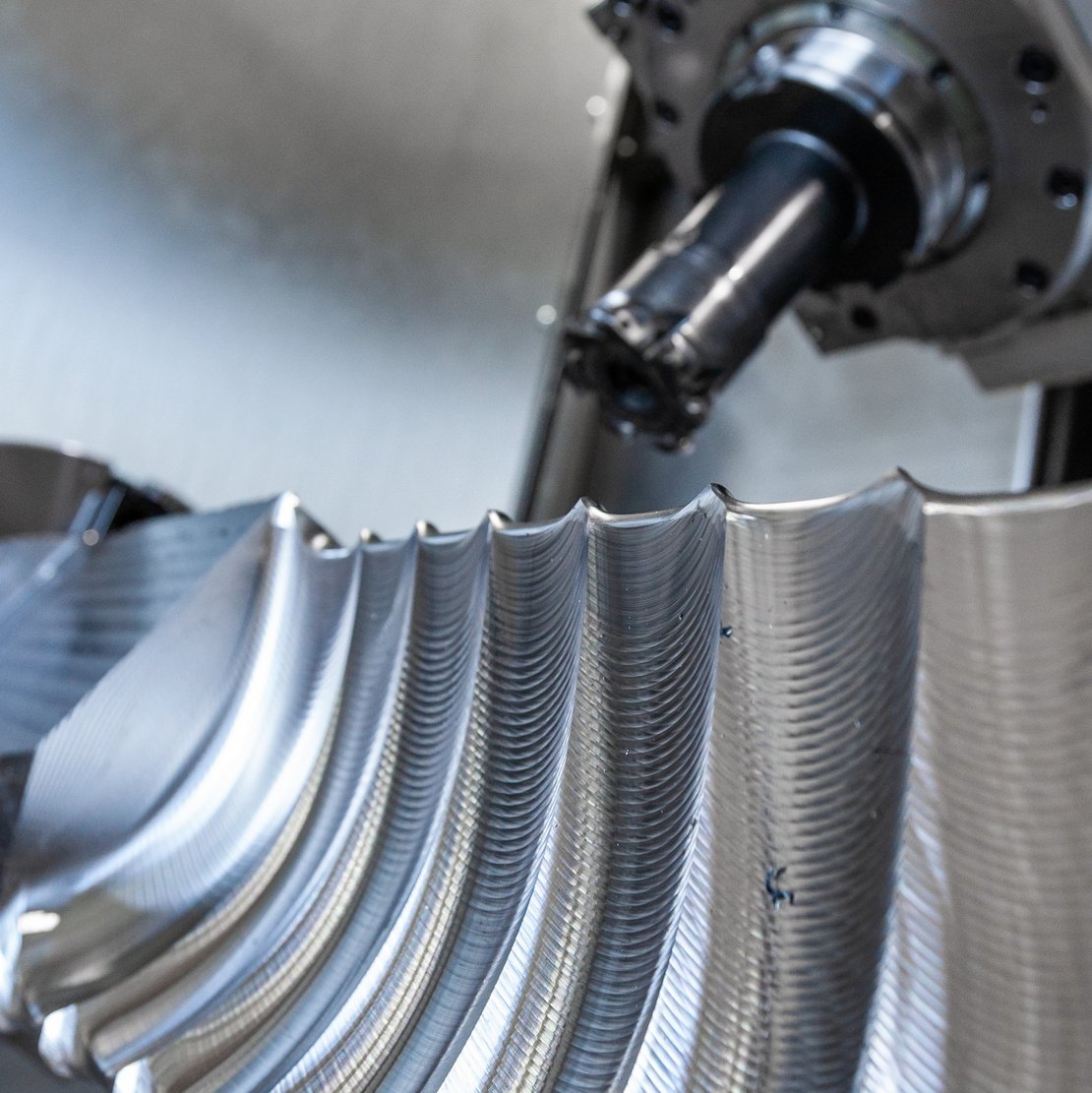

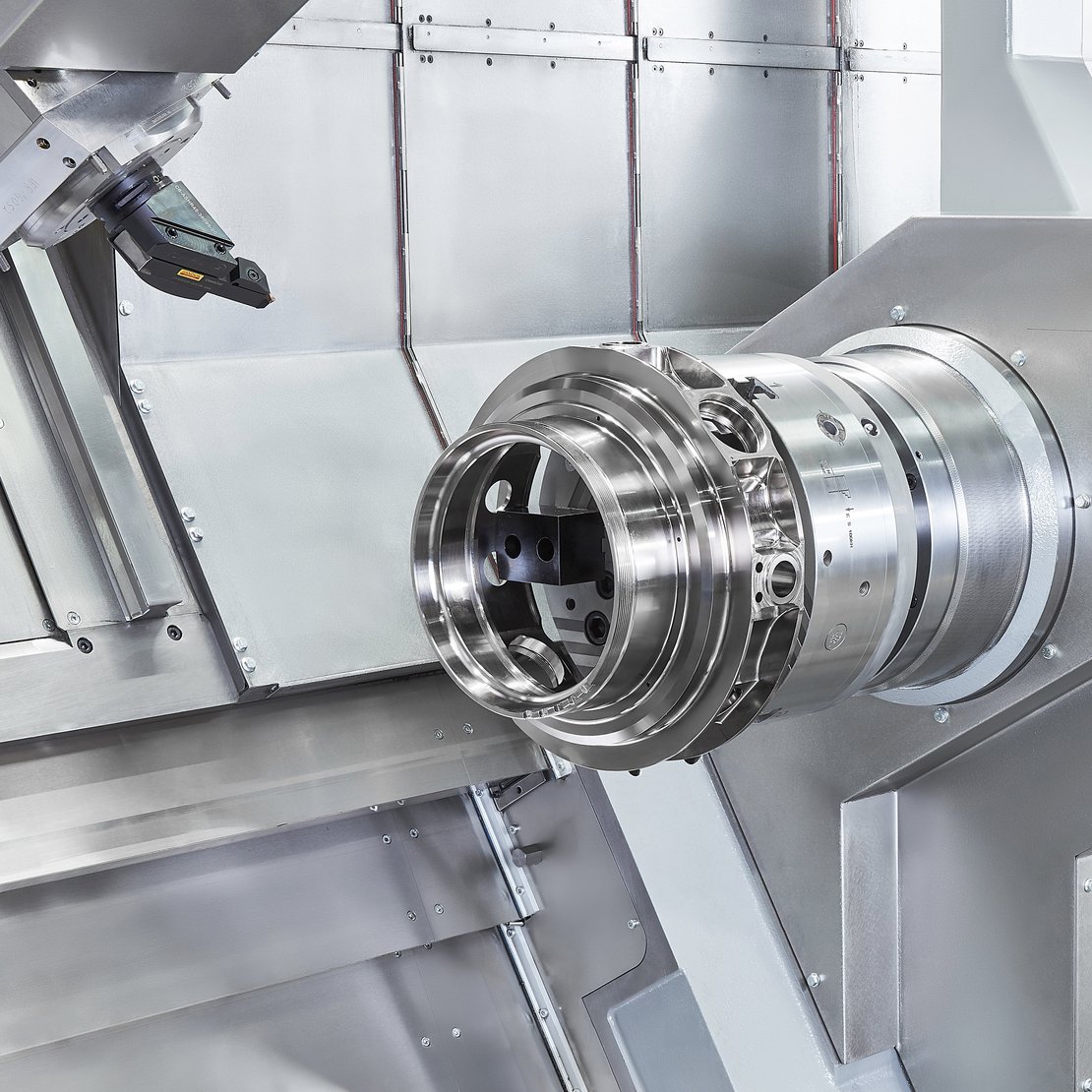

With the M50 and M50-G MILLTURN series, WFL Millturn Technologies is presenting a new generation of multifunctional turning-boring-milling centres for one-hit machining of complex chuck and shaft parts up to 670 mm swing over bed.

Turning, milling, drilling, hobbing, shaping, gun drilling as well as ID machining can be performed under any angle of the tool. The interpolation of up to 5 axes makes machining of any geometrical profile possible.

Highlights at a glance

- Wide distances between guideways for the stable accommodation of big steady rests

- Pick-up magazine for long tools with standard tool interface

- B-axis turning

- 4-axis turning

- Workpiece transfer

- High-precision measuring with integrated measuring probe

M50 | M50-G | ||

|---|---|---|---|

| Nominal center distance | mm | 1000/2000/3000/4500/6000 | 1000/2000/3000/4500/6000 |

| Swing - ø over Top slide | mm | 670 | 670 |

| Max. Turning- ø between centers | mm | 670 | 670 |

| Max. power, Turning spindle 40% (100%) duty cycle | kW | 54(37)/55(45)//56(40)/80(60) | 54(37)/55(45)//56(40)/80(60)///55(45) |

| Max. torque, Turning spindle 40% (100%) duty cycle | Nm | 2000(1400)/1830(1500)//3200(2320)/3600(2740) | 2000(1400)/1830(1500)//3200(2320)/3600(2740)///1830(1500) |

| Max. spindle speed, Turning spindle | min-1 | 3300/2500//2600/2600 | 3300/2500//2600/2600///2500 |

| Max. power, Miling spindle 40% (100%) duty cycle | kW | 33(27)//40(35) | 33(27)//40(35) |

| Max. torque, Milling spindle 40% (100%) duty cycle | Nm | 284(233)/213(175)//480(420)/300(263) | 284(233)/213(175)//480(420)/300(263) |

| Max. spindle speed, Milling spindle | min-1 | 9000/12000/*//5000/8000 | 9000/12000/*//5000/8000 |

| Swiveling angle B - axis | degree | -110...+110 | -110...+110 |

| Travel Y - axis | mm | 400(-175...+225) | 400(-175...+225) |

| Travel X - axis | mm | 800(-20...+780) | 800(-20...+780) |

| Tailstock | Type | Mechatronic | - |

| Tool magazine | number | 50/100/150/200//36/72/108/144 | 50/100/150/200//36/72/108/144 |

| Control SIEMENS | Type | SINUMERIK ONE | SINUMERIK ONE |

Ergonomic industrial design

Optimal view of the workpiece

- Large safety windows provide the best possible overview of the working area

- Optional spin windows

- Innovative and energy-saving lighting concept with LED lamps

Machine operation made easy

- Tiltable 19-inch display

- Ability of the operator panel to travel along the full length of the working range as far as the tool magazine

Easy maintenance

- Clear and logical structure of the control cabinet allows easy maintenance

- Excellent access to components requiring regular maintenance

- Hydraulic unit on extendable drawer