MACHINE INSPECTION

To keep your MILLTURN fit

Without an ongoing service agreement, a specific machine inspection is a sensible preventative maintenance measure. After a professional inspection, you will be given a detailed assessment of the condition of your MILLTURN. Based on that inspection, further maintenance measures can be planned efficiently.

- Specific machine inspection as preventative maintenance

- Detailed determination and documentation of the condition of the machine

- Competent consulting in terms of further measures

- Enables timely action

- Fixed price for each specific machine inspection

Drive belts

Inspection of the drive belts, including all axes and spindles in terms of wear and dirt.

Scrapers

Inspection of all guideway scrapers in terms of wear and correct scraping positions.

Telescopic sheets

Inspection of all telescopic covers in terms of wear, tightness, ease of movement and mechanical deformation.

Guideways

Inspection of all guideways and linear guides in terms of wear and damage.

Backlash on reversal

Inspection of all axes in reverse mode.

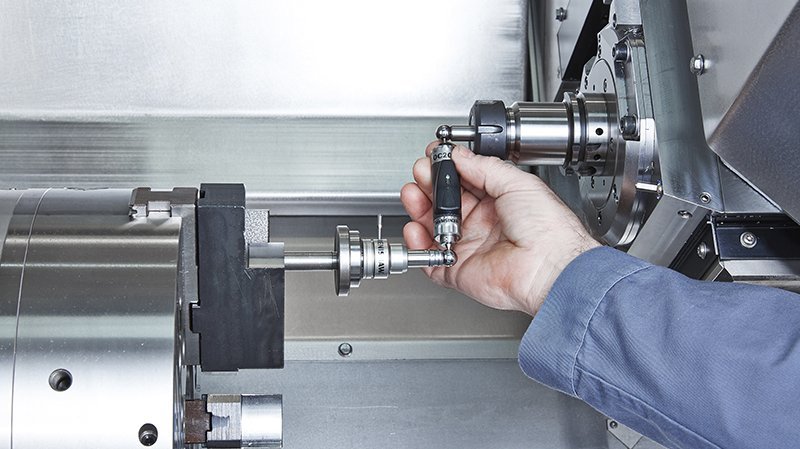

Tool clamping package

Determination of the pull-in force of the tool clamping package.

Tool changer

Review of the entire process of changing a tool in terms of the exact handover positions.

Geometry check

Inspection of the entire machine geometry in terms of accuracy.

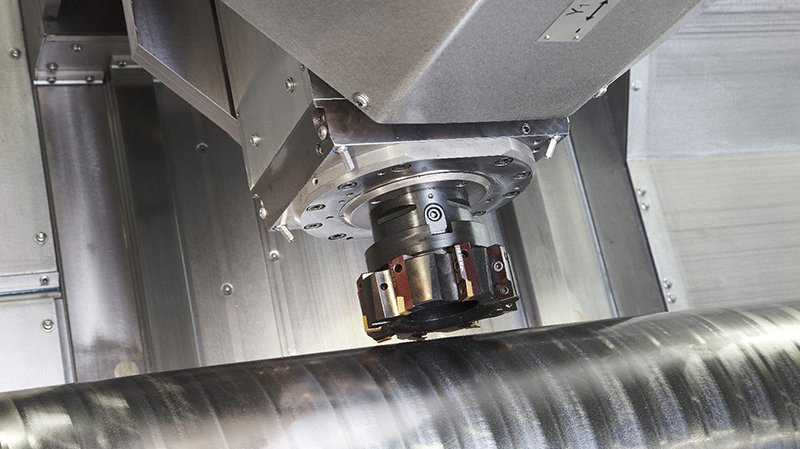

Bearing clearance of the milling spindle

Determination of the bearing clearance and run out errors on the milling spindle.

Laser measurement and circularity test

Inspection of all axes by way of laser measurement and the circular motion of the milling spindle by way of the circularity test.