WFL programming solutions

Programming and simulation in its simplest form

WFL is using its decades of experience to offer well-engineered software solutions relating to the manufacturing process with a MILLTURN complete machining centre. The programming editor Millturn PRO, the simulation software CrashGuard Studio and the collision prevention software CrashGuard are perfectly suited to the requirements of complete machining. WFL offers an unbeatable comprehensive package for cost-efficient and reliable production together with excellent detailed solutions for process reliability, ease of use and connectivity.

Programming made easy.

The technology cycles from WFL cover an extremely broad range of standard and special technologies for all conceivable applications. These program modules, which only require the input of parameters, make it possible to carry out efficient programming directly via the machine control system or on a PC. Programs can therefore be created for both complex and simple workpieces in only a short period of time.

WFL offers the following products in this area:

CrashGuard Studio

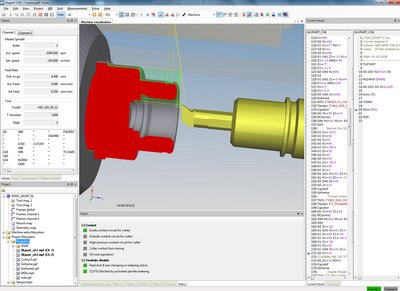

Offline simulation with material removal

The most effective way to test and optimise new or modified CNC programs is through the use of the 3D simulation software CrashGuard Studio. These tests can be carried out at an external programming station or directly on the machine control system. By optimising the machining process and ensuring faults are corrected early, users can expect a significant reduction in the risk of collisions and scrap, while also minimising unproductive downtimes. This unlocks new potential and offers clear competitive advantages.

CrashGuard Studio is the perfect addition to any CAD/CAM software, as well as to the WFL collision prevention software CrashGuard. With the help of material removal simulation, 3D geometries of workpieces can be exported in any machining state. The data for workpieces, tools and clamping devices can be transferred as required.

Benefits of CrashGuard Studio

- Complete and true-to-life simulation of NC programs with material removal directly via the programming station or machine control system

- Shorter run-in time for the machine, thus significantly increasing productivity

- Realistic calculation of machining time

- Optimisation of the entire machining process and reduction in the risk of scrap

- Increase in efficiency thanks to early error detection

- Different machining units such as counter spindles or bottom slides can be aligned in a time-efficient manner Unproductive downtimes can be reduced to a minimum

- Simulation of all cycles possible (whether from WFL or created by the customer)

- Integrated 3D measurement functions for optimal configuration of tools

- Perfect compatibility with and ideal addition to all CAD/CAM systems

- Training tool for programmers and operators

- Simple and cost-effective feasibility assessments, especially in the case of complex workpieces

- Can be switched to manual operation during program simulation

- NC programs or post-processors can be tested before a machine is even delivered

- True-to-life simulation of in-process measurements

MillturnPRO

Programming in CrashGuard Studio

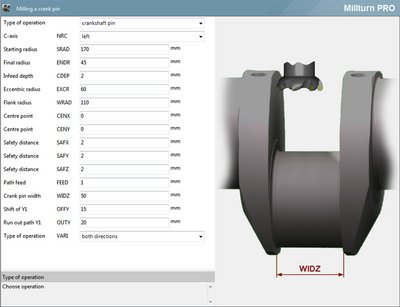

The interactive graphics of the Millturn PRO programming editor enable NC programs to be created efficiently and easily, making CrashGuard Studio a universal programming system for even the most demanding workpieces (without freeform surfaces). Programming can be carried out at an external programming station or directly via the machine control system. The programmed machining operations can be thoroughly reviewed step by step in CrashGuard Studio. The significantly reduced programming time achieved with CrashGuard Studio makes it the perfect solution for situations where a fast response time is called for.

Easy-to-understand dialogue screens make it easy to apply all WFL cycles. The cycle parameters are pre-populated with typical values to save valuable programming time. Simple programming with the help of graphics.

By entering only a few additional details entire machining operations can be programmed, consisting of many different lines of NC program code with tool selection function, start-up, machining and tool retraction.

- Significantly reduced programming time

- Easy-to-understand dialogue screens make it easy to apply all WFL cycles

- The cycle parameters are pre-populated with typical values to save valuable programming time

- Programming of entire machine operations consisting of many different lines of NC program code with tool selection function, start-up, machining and tool retraction

- Improved view in NC program thanks to text folding

- The NC program always remains readable and can be optimised without compromise

- Re-translation in NC Editor to the dialogue level, even for machining operations

- Step-by-step review of machining operations thanks to integrated simulation

- Programming of 2D contours can be done in a flash with the contour editor with mouse support and interactive graphics

- The available machining strategies with automatic cut distribution cover all bases

ScrewCAM

Programming in CrashGuard Studio

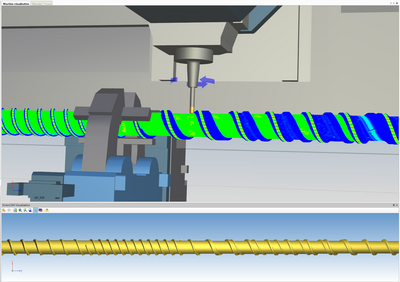

ScrewCAM is a software expansion for CrashGuard Studio that was developed for the production of plasticising screws for the plastics industry. 2D drawing data or parameters are sufficient for modelling screw geometry; a 3D CAD model of the screw is not necessary. There are four steps in the screw production process: modelling, NC program creation, simulation and production.

Interactive modelling of screw geometry based on 2D drawing data and parameters through input of diameters, pitches, wall inclines, radii, bar or channel widths and depth profiles with 2D modulo representation of bar contours at cylinder development level and a preview of the 3D target geometry of the screw.

Creation of the NC program by defining the individual machining processes and selecting tools, cutting speeds, infeed depths, feed rates, stock allowances, etc. The NC program is generated automatically. If modifications are made at a later stage, all of the steps affected will be recalculated accordingly. When it comes to wall finishing, ‘best-fit’ tool positioning allows standard tools to be used instead of expensive form cutters.

3D simulation in CrashGuard Studio® so that the entire NC program can be checked for collisions and the correctness of the workpiece geometry produced using a material removal simulation and geometrical verification against the 3D target geometry of the screw.

Production on the machine.

- 2D drawings form the basis for programming

- 3D object previews can be generated

- All machining steps for manufacturing the workpiece are in a single software package

- Can be simulated in CrashGuard Studio

- Cost savings as a result of using standard tools instead of form cutters

Maintenance service contract

Always stay up to date

With the maintenance service contract for CrashGuard Studio®, users will always stay up to date.

- Valid for one year and for one licence

- Software updates/upgrades included

- A one-year maintenance service contract is included in the purchase of a licence or additional licence

- Web and email support included (cgstudio(at)wfl.at)

Request a maintenance service contract now