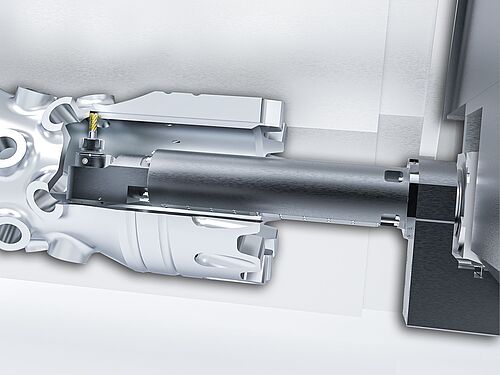

ID machining tool

A prismatic tool accomodation allows the automatic use of heavy ID-machining tools such as boring bars, solid drilling tools or rotating deep hole boring tools with internal coolant supply. Vibration damped boring bars can be used up to a dia. – length ratio of 1:14.

- Powerful - for maximum power transmission

- Reliable - for maximum cutting volume

- Flexible & agile - for machining of hard to access area of the workpiece

- Intelligent - equipped with sensors to protect workpiece, tool and machine

ID-turning and ID-boring

From deep hole drilling, ID turning to chamber boring, WFL is focusing on highest accuarcy, security and quality. In addition to the technical requirements for internal machining, WFL also provides support regarding the preparation of machining strategies. Extensive process know-how as well as suitable control mechanisms ensure a reproducible high quality.

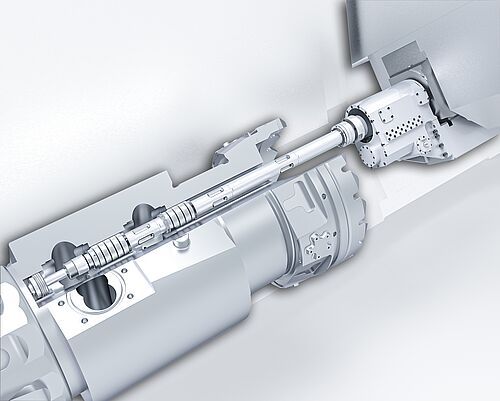

CNC special contour bar

By means of CNC contour boring bars, internal contouring becomes possible in deep hole bores (centric and excentric), e.g. bottle borings or seat pocket machining. The WFL product range comprises the required driving heads for coupling with the optional U-axis. CNC facing heads can be used as well.

WFL system boring bar

Damped boring bars can be securely mounted onto the turning-boring-milling unit by means of a special dovetail accommodation. In addition, the WFL system boring bars allow automatic changing of cutting heads. For boring bars with a diameter of up to 220mm and a machining length of up to 2000mm, WFL offers a separate slide providing maximum stability.