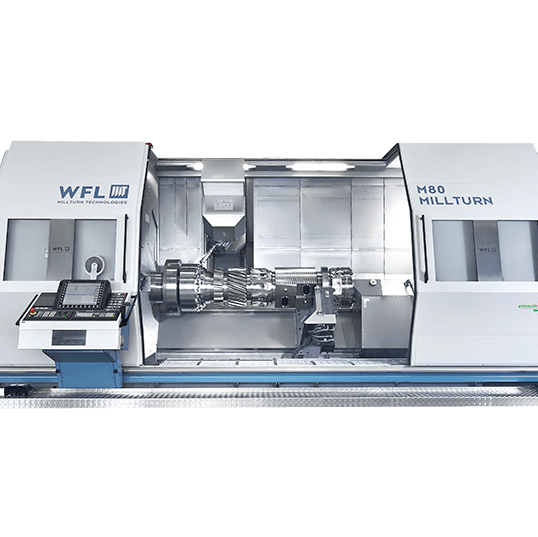

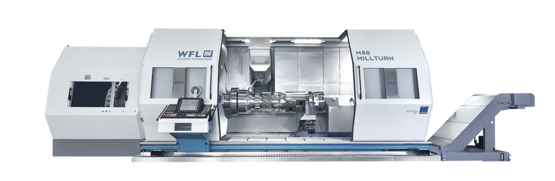

M80, M80-G & M80X, M80X-G & M85, M85-G MILLTURN

The all-rounder

An essential feature of the M80 MILLTURN is the enormous variety of configurations possible out of the modular machine concept together with the best size for the individual machine configurations. The machine concept is based on minimized distances of tool and workpiece to the bed and widest possible guideway distances resulting in an optimum situation for rigidity and ideal geometries.

All center distances (except 1000 mm) are also available in a counter spindle version and for a further productivity enhancement an additional tool turret can be offered. Due to the innovative machine design the bottom guideways do not require any telescopic covers. Just straight stainless steel sheet metal makes perfect chip flow.

The new tool magazine is accessible from the front of the machine and is a compact, stable and truly maintenance-free unit. A highly dynamic tool changer with rack and pinion drive is equipped with linear axes thus avoiding any centrifugal forces caused by rotation so even tools with 35 kg in weight are handled safely and quickly.

Highlights at a glance

- 150 bar coolant pressure

- Tool change in any Z-axis position

- Heavy drilling and boring

- Gear hobbing

- Workpiece transfer

- Active B-axis

M80 | M80-G | ||

|---|---|---|---|

| Nominal center distance | mm | 1000/2000/3000/4500/6000/8000 | -/2000/3000/4500/6000/8000 |

| Max. Turning- ø between centers | mm | 1000/1000/1000/1000/980/950 | -/1000/1000/1000/980/950 |

| Max. power, Turning spindle 40% (100%) duty cycle | kW | 56(40)/80(60) | 56(40)/80(60) // 60(40)/90(60) |

| Max. torque, Turning spindle 40% (100%) duty cycle | Nm | 3420(2440)/5860(4500) | 3420(2440)/5860(4500) // 3000(2000)/4800(3200) |

| Max. spindle speed, Turning spindle | min-1 | 2400/1600 | 2400/1600 // 2400/1600 |

| Max. power, Miling spindle 40% (100%) duty cycle | kW | 58(45) | 58(45) |

| Max. torque, Milling spindle 40% (100%) duty cycle | Nm | 640(500)/400(310) | 640(500)/400(310) |

| Max. spindle speed, Milling spindle | min-1 | 5000/8000 | 5000/8000 |

| Swiveling angle B - axis | degree | 220(-110...+110) | 220(-110...+110) |

| Travel Y - axis | mm | 650(-300...+350) | 650(-300...+350) |

| Travel X - axis | mm | 900(-20...+880) | 900(-20...+880) |

| Tailstock | type | Mechatronic | - |

| Tool magazine | number | 36/72/108/200 * | 36/72/108/200 * |

| Control SIEMENS | type | SINUMERIK ONE | SINUMERIK ONE |

M80X | M80X-G | ||

|---|---|---|---|

| Nominal center distance | mm | 1000/2000/3000/4500/6000/8000 | -/2000/3000/4500/6000/8000 |

| Max. Turning- ø between centers | mm | -/1000/1000/1000/980/950 | -/1000/1000/1000/980/950 |

| Max. power, Turning spindle 40% (100%) duty cycle | kW | 56(40)/80(60) | 56(40)/80(60) // 60(40)/90(60) |

| Max. torque, Turning spindle 40% (100%) duty cycle | Nm | 3420(2440)/5860(4500) | 3420(2440)/5860(4500) // 3000(2000)/4800(3200) |

| Max. spindle speed, Turning spindle | min-1 | 2400/1600 | 2400/1600 // 2400/1600 |

| Max. power, Miling spindle 40% (100%) duty cycle | kW | 58(45) | 58(45) |

| Max. torque, Milling spindle 40% (100%) duty cycle | Nm | 640(500)/400(310) | 640(500)/400(310) |

| Max. spindle speed, Milling spindle | min-1 | 5000/8000 | 5000/8000 |

| Swiveling angle B - axis | degree | 220(-110...+110) | 220(-110...+110) |

| Travel Y - axis | mm | 650(-300...+350) | 650(-300...+350) |

| Travel X - axis | mm | 1050(-20...+1030) | 1050(-20...+1030) |

| Tailstock | type | Mechatronic | - |

| Tool magazine | number | 36/72/108/200 * | 36/72/108/200 * |

| Control SIEMENS | type | SINUMERIK ONE | SINUMERIK ONE |

M85 | M85-G | ||

|---|---|---|---|

| Nominal center distance | mm | 1000/2000/3000/4500/6000/8000 | -/2000/3000/4500/6000/8000 |

| Max. Turning- ø between centers | mm | 1100/1100/1100/1100/1080/1050 | 1100/1100/1100/1080/1050 |

| Max. power, Turning spindle 40% (100%) duty cycle | kW | 56(40)/80(60) | 56(40)/80(60) // 60(40)/90(60) |

| Max. torque, Turning spindle 40% (100%) duty cycle | Nm | 3420(2440)/5860(4500) | 3420(2440)/5860(4500) // 3000(2000)/4800(3200) |

| Max. spindle speed, Turning spindle | min-1 | 2400/1600 | 2400/1600 // 2400/1600 |

| Max. power, Miling spindle 40% (100%) duty cycle | kW | 58(45) | 58(45) |

| Max. torque, Milling spindle 40% (100%) duty cycle | Nm | 640(500)/400(310) | 640(500)/400(310) |

| Max. spindle speed, Milling spindle | min-1 | 5000/8000 | 5000/8000 |

| Swiveling angle B - axis | degree | 220(-110...+110) | 220(-110...+110) |

| Travel Y - axis | mm | 650(-300...+350) | 650(-300...+350) |

| Travel X - axis | mm | 1050(-20...+1030) | 1050(-20...+1030) |

| Tailstock | type | Mechatronic | - |

| Tool magazine | number | 36/72/108/200 * | 36/72/108/200 * |

| Control SIEMENS | type | SINUMERIK ONE | SINUMERIK ONE |

U-Axis

The use of driven tools with additional NC drive such as facing heads (D´Andrea) or special boring bars for seat pocket machining (e.g. Cogsdill, ITS) requires an additional NC axis. WFL offers such an axis (U-axis) as an option. Even after the integration of this U-axis, the option of angular machining remains. This option can offer enormous cost reduction potentials, especially for the aerospace industry as well as for manufacturers in the oil and gas industry. In order to ensure the necessary stability, only the prismatic tool interface is used to accommodate tools on the U-axis. Automatic tool change is carried out either via the pick-up magazine or the prismatic tool changer.

- Manufacturing of pockets (seat pocket)

- Internal machining with damped boring bar

- CNC special contour boring bar (radial feed out using the U-axis)

- Deep hole drilling with automatic coolant docking

- Internal milling with angular head

- CNC facing head for complex spindle operations