LASER CLADDING

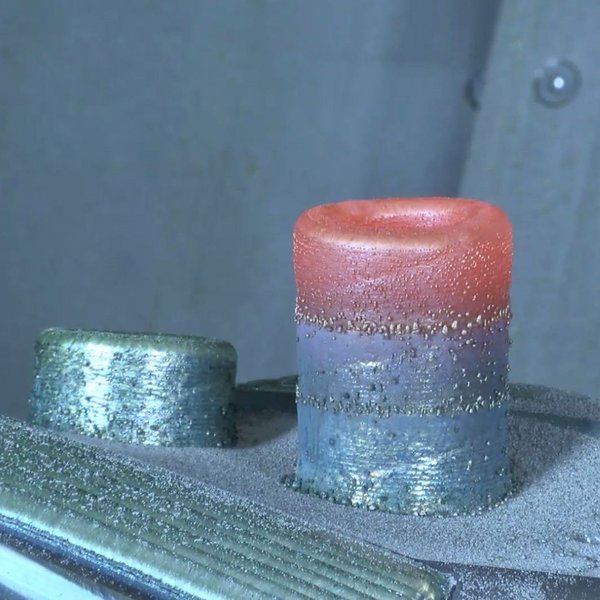

During cladding, an inert gas is used to focus the powdered metal on a point of impact through a ring nozzle. The laser beam is also focussed on this area, which results in the creation of a melt pool. The molten powdered metal settles in this pool and then solidifies. The width and height of the material cladding that is being applied is determined by precisely balancing the energy applied and the traversing speed of the laser beam with the amount of powder being fed through the machine.

As with traditional inert gas welding, the inert gas prevents oxidisation processes while also acting as a carrier and transport gas for the powder particles. The powder particles are between 100 and 150 µm in size, so they are large enough to be filtered out by the 40 µm filter. This ensures that excess powder particles are not able to interfere with the functioning of the machine in the long term. Depending on the process parameters, the application rates produce cladding thicknesses of 1.0 mm and above.