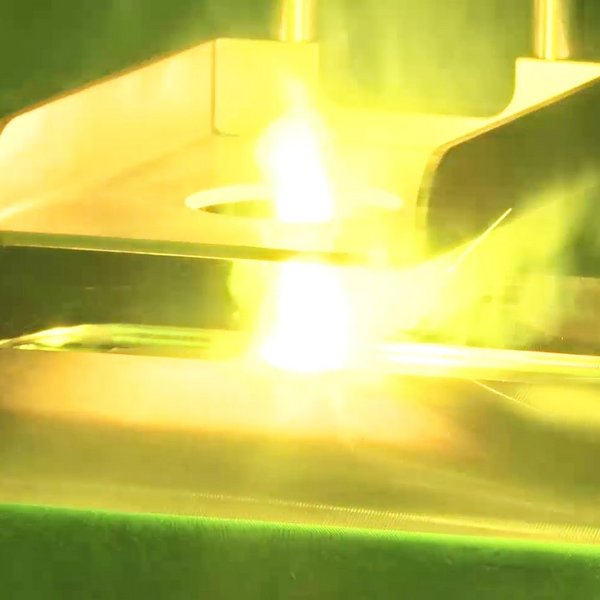

LASER WELDING

For laser beam welding a head with a different lens is required. During gap welding and deep gap welding, a far narrower focal point is required for the laser beam in order to achieve increased welding depth on the one hand and to keep the heat-affected zone as small as possible on the other. The aim is to develop an alternative to narrow deep bore holes, for example. In this way, a cooling channel can first be milled into the outer contour of a component, for instance, and a covering can then be welded over the top of it. This not only makes the machining process easier, it also offers completely new possibilities in terms of shape. It will also be possible to weld rotating parts together concentrically. These would previously have been manufactured in parallel on the main and counter-spindle of the machine.