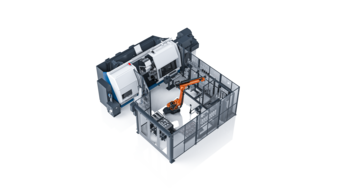

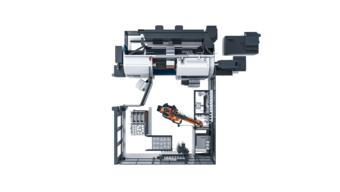

Automation M35-G – Articulated robots

An automated cell containing an articulated robot paired with a M35-G MILLTURN offers numerous benefits that boost efficiency and quality in the manufacturing industry.

Modern production technology calls for increasingly flexible and efficient solutions in order to meet market requirements – solutions such as an automated cell that connects an articulated robot to a M35-G MILLTURN. With this combination, you can carry out complex machining processes quickly and accurately while also reducing production costs. Thanks to automation, companies can increase productivity and the quality of their products while reducing their employees' workload.

Integrating an articulated robot into a M35-G MILLTURN is a forward-looking investment which helps companies to remain competitive and face the challenges of the modern world of manufacturing.

Advantages

- Continuous operation

- Quick cycle times

- Repeat accuracy

- Minimises errors

- Multifunctionality

- Quick changeover times

- Lower labour costs

- Lower operating costs

- Ergonomics

- Improved safety

- Easy expansion

- Easy component integration

Advantages

1. Increased productivity:

Continuous operation: Articulated robots can work around the clock, without taking a break. With a guaranteed material flow, production can take place 24/7, which significantly increases production capacity.

Quick cycle times: Robots can handle workpieces quickly and precisely, which minimises cycle times and lead times.

Tool change: Tools can be loaded and removed by the robot, meaning that additional tools can be stocked in the cell and exchanged during the process.

Clamping device changeover: Industrial robots can also change the clamping devices without intervention from operators, which again increases output.

2. High precision and quality:

Repeat accuracy: Robots work with higher repeat accuracy, which results in consistent quality of the manufactured parts.

Minimisation of errors: Automation reduces human error, improving the overall production quality.

3. Flexibility and adaptability:

Multifunctionality: Articulated robots can be programmed to carry out a multitude of tasks, including material handling, loading and unloading machines, changing clamping devices, changing tools, and assembly work.

Quick changeover times: Thanks to parameter programming, changes to the production process can be implemented quickly, increasing adaptability to new product requirements.

4. Cost-effectiveness:

Lower labour costs: Using robots reduces labour costs, as less manual intervention is required and operating personnel can work on other tasks.

Lower operating costs: Automated systems can make more efficient use of energy and minimise wear on tools and machines.

Less production downtime: Using automated systems can increase the availability of machine tools. No waiting during changeover of parts or clamping devices.

5. Better working conditions:

Ergonomics: Heavy lifting and monotonous tasks are taken on by the robots, reducing the physical strain on employees.

Improved safety: Robots can work in hazardous environments, lowering the risk of an accident for human workers.

6. Scalability:

Easy expansion: If demand increases, automated cells can be easily expanded or adapted by integrating additional robots or machines. Likewise, processes within the plant can be switched over with ease, increasing effectiveness even further.