Aequs Aerospace France: innovation driving industrial excellence

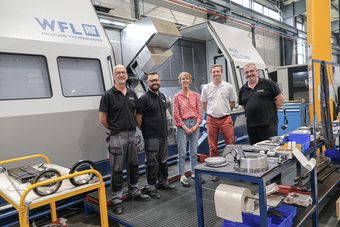

Based in Cholet (France), Aequs Aerospace is a key player in the machining of complex parts for the aerospace industry. With a 65-strong team and experience spanning decades, the company epitomises industrial excellence. This success is down to a winning combination of highly qualified employees on the one hand and cutting-edge technology on the other. Taking the starring role are two WFL M120 MILLTURNs that have provided unparalleled performance in precision engineering over many years.

A story of partnership and technology

Aequs Aerospace France has been known by its new name – derived from the Latin "aequus" (meaning equal) – since 2016. The choice of name reflects the company's philosophy that has a particular emphasis on equality and partnership with all its stakeholders, whether they be employees, customers, partners or suppliers. This collaborative approach is also evidenced by Aequs's commitment to creating enduring value through innovative and efficient global ecosystems.

The Cholet site, the group's centre of excellence for the manufacture of engine parts and landing gear, enjoys a unique synergy between tradition and modernity. Aequs combines proven expertise with cutting-edge technology to meet the growing demands of the aerospace sector. Their approach is perfectly exemplified by the choice of WFL, specifically the M120, for their machining needs.

The WFL machines: a huge asset for Aequs

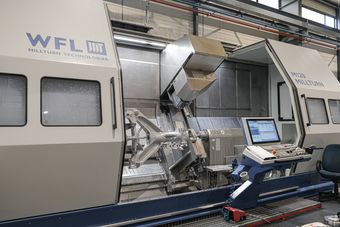

For Aequs, having the right equipment is key. The company has two WFL M120 MILLTURNs in its machine park, capable of performing turning and milling operations on large parts with exceptional precision. These machines are central to production at the Cholet plant and play a crucial role in manufacturing critical aerospace components, such as engine parts and landing gear.

Laurent Gouin, HSE Technical Manager and a prominent figure at the company, was there when the machines first joined the production line at the plant, and saw first-hand the difference they made. Gouin, who has been with Aequs for more than 30 years, received training in Linz (Austria) when the first M120 was acquired in 2000, and similarly on acquisition of the second machine in 2004. In his words: "We heard about these machines through our customers and, having done so, were left in no doubt of the need to invest in equipment capable of performing complex operations on large parts. The same machine now allows us to carry out a whole range of different operations. Looking back over our experience, I can affirm that these machines are absolutely central to our production process."

The M120 from WFL is more than just a machine; it's a strategic tool that enables Aequs to remain competitive on the global market. Thanks to its versatility the M120 can take demanding specifications in its stride, while also boasting an impressively long service life. "We have been using our machines for 24 years, and they still run like new. We are hugely impressed by their quality and how tough they are", adds Gouin.

Successful upgrade process

Aequs took the decision to upgrade its machine park in 2024. One of the two M120s was replaced with a reconditioned model, a complex operation that was more than a year in the planning. Frédérique Baudin, Production and Maintenance Manager, explains the challenges surrounding this ambitious project: "The main objective was to ensure the continuity of deliveries to our customers. For this to happen, we had to plan around production needs, adhere to a tight schedule, and ensure a smooth transition between the old and new M120."

The refurbishment process was planned and organised down to the last detail. WFL technicians delivered and installed the new reconditioned machine over a single day. On the same day, they took away the old M120, which had been bought back by WFL and was due to be refurbished in Austria for another customer. "The plan ran like clockwork. We scheduled a production stop of three weeks during the end-of-year holidays to minimize the impact on our operations. This meticulous planning was essential for the success of the switchover", believes Baudin.

The success of the project was also down to the part played by the maintenance teams and operators. Noël Bellanger, operator and fitter, was among those responsible for bedding in the new machine. "The main difference lies in the numerical control system, which has been completely redesigned and updated. However, the short training session we received allowed us to get up and running again without any delays in production and without any downtime", he explains. The new machine engenders confidence among operators who appreciate working with a tool that is both modern and reliable.

Claude Octave, Team Leader Maintenance, expresses his enthusiasm: "The process of integrating the new machine into production ran perfectly and went without a hitch. The seamless switchover, meticulous planning and coordination with the WFL team meant no production time was lost. Technical support from the team and their willingness to listen to us was crucial in ensuring the success of this operation. Now we have seen this process run so successfully, we have no reservations about replacing the second M120, which has now been in operation for 24 years."

Commitment to sustainable industry

Innovation at Aequs is not just about equipment; it extends to a vision for sustainable industry. The Group is seeking to be carbon neutral in electricity consumption by 2025 thanks to investment in renewable energy, including the installation of solar panels at its sites in India.

Alongside this commitment, the company is pursuing a strategy of insourcing more processes in order to reduce transport operations and therefore minimize environmental impacts. Projects are in hand to bring production stages that were previously outsourced, such as the surface treatment of parts, back in house. This would allow the company to reduce transport operations while also boosting internal expertise.

A new approach to safeguard unique expertise

Olivier de Rohan Chabot has led operations at the Aequs Aerospace France Cholet site since January 2022, with the aim of improving the work environment and injecting new momentum into the group's innovation centre. Under his leadership, the company is supported by a highly skilled team that continues to develop its competencies while strengthening its strategic role within the group.

The technical parts produced in Cholet, which account for around 10% of global turnover, illustrate the importance of the site to Aequs's business. To meet the challenges of today's aerospace industry, which is undergoing significant upheaval, the company relies on continuous innovation and adaptation to the new realities of the post-pandemic market.

A future marked by growth and innovation

Aequs Aerospace France is gearing up to meet the challenges of an expanding aerospace sector, with demand growing by more than 30% year on year. To remain competitive, the company is upgrading its production facilities and pursuing a sustainable strategy in order to ensure its capacity to meet the future needs of the industry. "That's why we took the decision to upgrade one of the M120s – to enable us to increase capacity on this machine," explains de Rohan Chabot.

The Cholet site is central to this dynamic, and continues to play a crucial role thanks to a combination of cutting-edge technology and proven expertise. Aequs is a model for how tradition and innovation can coexist harmoniously and help maintain a leading position in a demanding market. The WFL machines, critical to their success, will continue to be at the heart of this quest for excellence. With a clear vision and ambitious goals, Aequs is well placed to drive innovation and grow sustainably in the coming years.