Automation with linear and area gantry

FRAI specialises in the development and production of flexible automation systems. Depending on the customer's requirements, different automation variants are used for automatic workpiece loading and unloading.

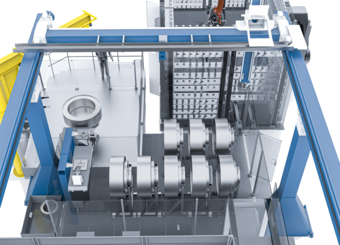

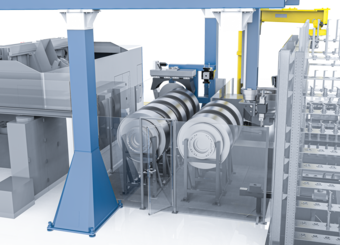

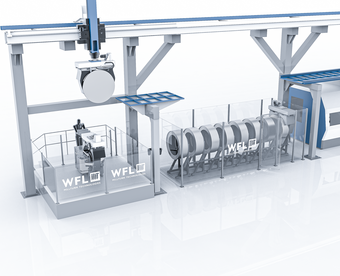

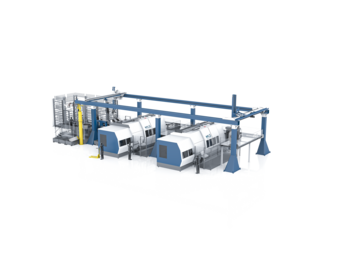

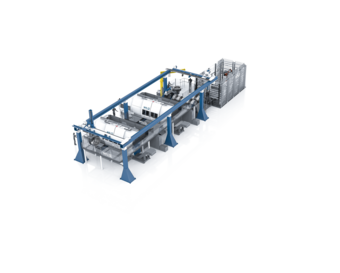

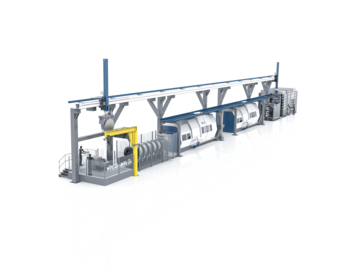

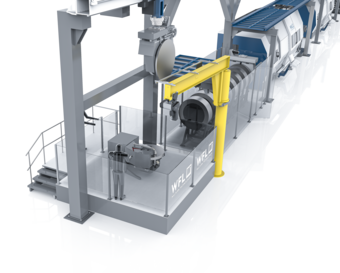

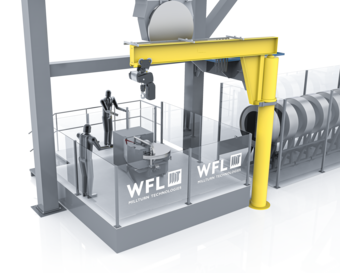

In addition to the classic handling solutions, WFL turnkey projects are equipped with a higher-level host computer system as standard. This "brain" takes over the entire logic and logistics from within the fully self-sufficient, flexible production cell. In addition to workpiece tracking and tool management, the system also transmits all operating data (operational data acquisition) to the MES (Manufacturing Execution System) provided by the customer. One of the most efficient automation variants for production processes is the gantry loader. With loading from above, the modular gantry loader enables unrestricted access to the machine while taking up very little space. The modularity inherent in the design means that long travel paths and large working areas can be realised and huge loads can be handled. The minimal space requirement is often a key advantage in small production areas, particularly when retrofitting automation solutions.

Linear and area gantries consist of the same basic assemblies:

- Machine(s)

- Gantry

- Set-up station for workpieces

- External tool magazine (if required)

- Buffer/lung/warehouse for multiple workpieces (mounted on jigs)

- Gripper changeover station (if required)

- Gripper for jig

- Gripper for tools

Advantages

-

Set-up station for workpieces: these are clamped on the jig or the finished part is removed

-

External tool magazine: saves costs compared with individual magazines for each machine

-

Warehouse for 8 jigs (optionally for more jigs): prolongs the autonomous time of the cell (unmanned shift)

-

Gripper changeover station: individual grippers for jigs and tools

-

Wide product range: Product variety is "infinitely" large thanks to the use of jigs.

-

Linear gantry: slim but long and high (installation height 10.5 m).

-

Area gantry: short and low (7.5 m) but wide.

-

We offer various scalable solutions depending on the space available on the customer's premises.

Mobile Robot Automation

The factory of the future requires mobility and flexibility. Intelligent, mobile robot units are now replacing static production lines. Mobile robots move independently around the room and provide absolute flexibility for industry.

Advantages of the mobile robot solution:

- Unrestricted layout design

- Machines can be integrated directly in the respective place of installation

- Hardly any additional interfering contours when the mobile robot is not in use, thereby guaranteeing unrestricted access for manual activities