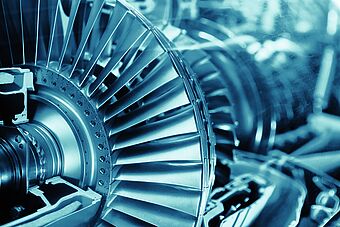

Complete machining of turbine blades

In times of growing cost pressure it is necessary to consider which opportunities may be available for future progress.To do so, WFL is employing its long-standing Expertise in complete machining. Today, strategies that are being continuously developed are required – not only in the aviation sector, but also in the energy technology sector and in the production of gas turbines, steam turbines, wind turbines or water turbines.

Stability, flexibility and durability are our aims with regard to complete machining. These attributes are not only fulfilled, but they also form part of our corporate philosophy. WFL offers a range of solutions that meet these goals and understands the requirements of its customers.

Using an example, WFL provides more accurate insights into the complete machining of turbine blades. WFL promises excellent results in terms of precision and the required production speed.

The process:

The unfinished component of the turbine blade is clamped on both the main and counter spindles. Perfectly balanced synchronous operation means that there are no restrictions in terms of speed or acceleration. Machining, from pre-roughing through to deburring, is performed using a total of 14 tools, which are changed independently and fully automatically. In order to achieve the best results, making the best use of software is critical to ensuring synchronous operation. The WFL process monitoring controls the operation and prevents the overloading of tools and machine. The extremely high precision of the MILLTURN complete machining centre makes high-quality results possible. Since the turbine blade can be machined from being clamped just once, the ingenious 5-axis operation promises considerable time savings with flexible production technology and maximum precision.

Advantages:

• Complete machining with a single clamping operation

• Constant cutting forces due to newly developed production strategy (less tool wear)

• Internal high-pressure coolant also enables the machining of high-alloy steels and super alloys

• Extremely quick and precise machining through synchronous spindle operation