Entering Earth's orbit more efficiently

ArianeGroup is a world leader in access to space, working for its institutional and commercial customers and ensuring Europe's strategic independence.

As the lead contractor for the European launchers Ariane 5 and Ariane 6, ArianeGroup is responsible for the entire life cycle of a launcher – from design, entire production, marketing and operation through its subsidiary Arianespace. ArianeGroup has a workforce of approximately 7,000 highly-qualified people in France and Germany and is equally owned by Airbus and Safran as a joint venture. The company is also the lead contractor for the French navy's ballistic missiles. ArianeGroup and its subsidiaries are internationally recognised specialists in aerospace equipment and propulsion, services and space surveillance. Their expertise is also used in other industrial sectors and in critical infrastructure.

-

7,000 employees in Germany and France

-

11 subsidiaries and majority holdings

-

50/50 joint venture between Airbus and Safran

-

Revenue of 3.1 billion euros in 2021

One of ArianeGroup's key sites is Ottobrunn near Munich. This is home to the ArianeGroup Liquid Propulsion Centre, where components for engines for European Ariane launchers are developed and produced. The focus is currently on the thrust chambers for the Ariane 6 main stage engine, the Vulcain 2.1, as well as the new re-ignitable upper stage engine, Vinci.

A glimpse into the world of space travel

Stefan Winter, Head of Production at Ottobrunn, provides us with some interesting insights during a tour of the production facilities: "We have almost 300 employees here in Ottobrunn, around 100 of whom work in production. All the processes for manufacturing our components take place in house so our lead time is very short. The majority of our processes are carried out in our production centre, from machining and welding (EB and TIG) to integration and quality testing. Electroplating and component cleaning take place in neighbouring buildings. These short distances are a huge advantage for us."

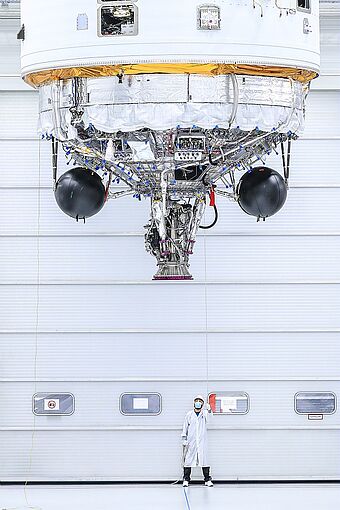

To leave the Earth and its gravitational pull behind, a rocket needs a lot of energy. The Ariane launchers achieve this with solid rocket boosters which deliver a thrust of around 13,000 kilonewtons and lift the 800-tonne rockets off the ground in the first two minutes after launch. The main stage with the Vulcain-2 engine which is started first after the countdown provides further thrust until the rocket has reached a height of approximately 160 kilometres around nine minutes after launch. In space, the upper stage takes over. This is powered by the HM7B engine for Ariane 5 and Vinci for Ariane 6. Depending on the mission, this engine is operational for around 15 minutes to put the upper stage with the satellites in space in the correct orbit.

The thrust chamber – the "heart" of the engine – for the Vinci engine for Ariane 6 was developed and manufactured in Ottobrunn.

Vinci works with cryogenic hydrogen and oxygen as the expander cycle: "First, the hydrogen flows around the combustion chamber, cools it and vaporises. The gases produced are used to drive fuel pumps and are then injected into the combustion chamber with the oxygen and burned," says Head of Production Stefan Winter. "There is only one expander cycle engine with this level of performance in the whole world. While conventional cryogenic engines almost always need a gas generator to drive the turbo pumps, this process works differently in the Vinci combustion chamber. With the expander cycle engine, although the hydrogen is allowed through the cooling channels to cool the chamber, the clever design means that this remains in the chamber for a long time, until it is as hot as possible. We then use the expanding gas to drive the turbo pumps. This is the big advantage of the Vinci engine."

M80 Millturn used to produce the Vinci engine

The majority of the engine parts from Ottobrunn are manufactured on a WFL M80 machine. This also includes the combustion chamber base body for the engine. First, the base body is prepared for turning of the inner contour. followed by the turning and milling of the outer contour. These two processes were previously carried out on two machines.

Thanks to the M80 Millturn, both processes – turning and milling – are combined and stable clamping is ensured. This is a huge advantage, especially for long, thin parts such as the Vinci combustion chamber. The zero point clamping system also provides maximum flexibility in production. "This is excellent," emphasises Winter.

A special alloy is used for the Vinci engine's base body. The patented copper-silver-zirconium alloy is characterised by high strength, an excellent heat transfer value and excellent machinability, which is particularly relevant for the Vinci chamber. Due to the aforementioned long, thin design, the material properties are very important. The material is first cast in blocks and then forged into the desired shape. Quality is ensured by means of ultrasound and then it is released for production.

The main production steps for a Vinci combustion chamber following delivery of the blank are turning, milling, electroplating, welding and finally finishing. Eighty percent of the workload is carried out with the M80.

Furthermore, cutting tests for the future are also carried out on the M80. The sturdy design and excellent kinematics provide more opportunities than thought. The first tests on the M80 Millturn have already been carried out with ceramic cutting materials. In the medium term, this process is also to be carried out on the WFL machine for Inconel and nickel. "I am very confident that we will be able to do this on the WFL machine," says Winter.

Innovative spirit for technology and personnel

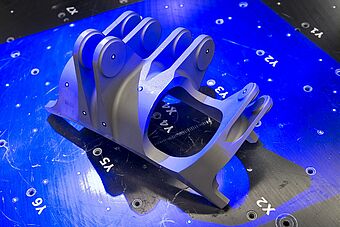

The Millturn is currently being used to manufacture other components besides the Vinci parts. The production team also uses the machine to produce satellite parts, as well as in R&D and for the construction of jigs. "This mix makes the best use of the machine's capacity," explains Stefan Winter. "I am also a fan of development work, as this is undoubtedly the workload of tomorrow and we have to continually face new challenges. For instance, we are currently working on components for the drive of the future – Prometheus for example."

The various versions of the Prometheus engine are to be driven by liquid hydrogen and liquid oxygen, as well as liquid oxygen and methane. These will be the first European engines with controlled combustion, enabling them to adapt to the launcher's flight conditions during the various phases of the mission. A digital system will provide control over a range from 30 to 100 percent maximum thrust. Prometheus will also be equipped with artificial intelligence and a health monitoring system that will enable diagnostics to be run on the engine's functioning.

The family of Prometheus demonstrators also benefits heavily from the latest 3D‑printing technology. Parts produced in this way account for 70 percent of the total weight of the engine.

"The WFL is very well suited for all of these exciting future projects," says Stefan Winter. It takes a motivated team of engineers and skilled workers to bring all this to life. In particular, highly complex machines such as the WFL require excellent, conscientious employees. When the finishing process for an item worth over half a million euros is taking place on the machine, it's a tense moment for the employees. "It is hard to find good employees, so we are always on the lookout for good skilled workers," states Winter.

"As Head of Production, it is particularly important to me to make the workplace interesting for employees. We mainly have senior engineers and technicians working in production at Ottobrunn. Good skilled workers are thirsty for knowledge and therefore need to be challenged and supported. Which is why we try to make the workstations as interesting as possible. For this reason, we are extending the programming with an additional programming system. Our medium-term goal is to have a pool of specialist personnel assigned to a machine and for this to also be independently implemented from programming to production of the component. We will then deploy this job rotation on other machines. Over the next 5 years, I want to change production to this effect. To do so, we need dedicated, qualified personnel," says Winter with conviction.

He also adds: "We are working with extremely expensive materials in accordance with the highest industrial standards and to the highest levels of quality. When a rocket is launched, there are no second chances, so we cannot make any mistakes. Quality-driven personnel are essential here and we have them."

Why Millturn?

"When it comes to machining times, our investment in the WFL M80 Millturn / 3000mm brought enormous added value," explains Stefan Winter. The WFL replaced a 3-axis lathe and a 3-axis milling machine. A zero point clamping system was implemented on the M80 so that setting-up is still very quick. This reduced the lead times and wait times by at least 30%. "One of the biggest advantages of the WFL machine is its large tool magazine. Because of the Inconel machining, we always have between four and six sister tools in use, so we need sufficient tool stations. This is not a problem thanks to the magazine's modular concept. If we need even more tools, we can just buy another tool turret disc. It's fantastic! In the past, three processes would require three NC programmes or more. Now we only need to release and maintain one NC programme for the same work. It also makes configuration management much easier, as there is less data to manage. This was a big step forward," explains Winter enthusiastically.

When asked why they opted for a Millturn and the M80 model, Winter responds: "Ultimately, the machine kinematics and references won us over. A quick supply of spare parts, components from renowned manufacturers and also the proximity to the manufacturer were also important to us."

The machine is equipped with a pick-up magazine and a WFL system boring bar. "We worked with WFL and Sandvik to procure a special 1.4 m-long boring bar so that in future we can also machine the Vinci's inner contour on the WFL." Winter continues: "To turn the inner contour on the WFL, we also developed a new device, which is now complete."

The machine also had to satisfy certain reliability and accuracy requirements. "The machine had to meet a tolerance of around 1/100 in the required working range. That is our requirement. Temperature influences play a huge role here, so our production hall is also air-conditioned. Therefore this is regularly checked and controlled by us and the machine is also temperature-monitored. WFL is really on the ball with the technology," says Winter.

Sealing surfaces are manufactured at ArianeGroup using the Utronix software cycle – the virtual U-axis. Circular surfaces are needed on certain workpieces, at every angle. "At around 135 degrees, we have to circular machine a sealing surface of 28 mm around a 20 mm hole with a boring bar. This then becomes increasingly larger. So the Utronix cycle is often in use here and is very important," says Winter in regard to the machining process.

Winter also emphasises how the new machine is an advantage when manufacturing a nozzle demonstrator: "We were asked to build a nozzle demonstrator. The challenge was to manufacture a complex conical inner contour with cooling channels. Thanks to the machine's stability, we were able to carry out the broaching process with a length of almost 500 mm. The combination of stability, flexibility and the required working area in the machine allows this kind of special machining to be tackled and carried out."