Experience is all well and good but iControl is better

The process monitoring system "iControl", process signals can be registered, evaluated and recorded in the CNC-kernel of the control with the maximum sampling rate. The monitoring strategies, such as "yellow limits," results in considerable advantages in tool breakage and tool wear monitoring. Another option of integrating is external sensors into process monitoring. The latter allows, for example, continuous monitoring and recording of performance data from coolant pumps or conclusions about the condition of spindle bearings.

The new "iControl" process monitoring system from WFL gives machine operators of the future a whole package of functions to ensure reliable, cost-effective (series) production processes. It is important that the machine and tools deliver maximum productivity when in use; at the same time, the process needs to be as stable and reliable as possible. The software package provided by WFL is extremely versatile and has a suitable monitoring tool for more or less every possible machining situation. The up to 16 process signals to be monitored are configured by WFL at the factory depending the machine configuration and displayed live on the control screen. Important process signals include the forces or torques of the NC axes and spindles, but also the signals from integrated sensors (vibration, pressure, flow, temperature, etc.). These are built into machine components or tools and can be used for a wide variety of applications such as process control, optimisation or monitoring.

The ultimate protection for machines, workpieces and tools

Process monitoring is typically grouped into functions for protecting machines, workpieces and tools, and functions for recording tool wear and ensuring constant productivity. Key new features for detecting tool wear and total breakage include the "wear limit" and the "tool missing limit." The goal was to develop a solution that would respond sensitively and reliably to all conceivable abnormalities in the machining process. This is complemented by a long-term data recording function for process data that WFL offers as an additional option under the name "iControl Data Recording", an important aspect specifically when it comes to the production of safety-related components.

Basic+ or Advanced+?

WFL is launching two design variants of the new iControl process monitoring system. Both versions include temperature sensors for recording the ambient temperature and the temperature of the milling spindle bearing housing. The "iControl Basic+" version monitors the designated maximum machine loads only and triggers a quick stop within <10 milliseconds in the event that these are exceeded. The “iControl Advanced+” variant includes a vibration sensor for recording the vibration speed and condition of the milling spindle bearing and also allows you to select a customised monitoring strategy for each machining operation and systematically develop a machining process with maximum productivity. The software was designed by WFL to make it easy and intuitive to select the ideal monitoring strategy, and combine it with other limits to suit. For example, the energy consumption per operation can serve as a comparative value when this operation is repeated, making it possible to detect excessive tool wear or a total breakage at an early stage during drilling and avoid serious damage. However, brief and isolated load peaks in the process sequence probably would not have any bearing on this operation and even small partial breakages on the cutting edge would be acceptable. As a result, the process would not be interrupted provided that the event was not identified as a total failure of the tool. By contrast, when it comes to finish turning, even the tiniest partial breakage on the cutting edge could lead to unacceptable surface quality, even though in principle the tool would still be functional. These types of events happen in a matter of milliseconds and are difficult or impossible for the operator to spot during machining. With dynamic monitoring enabled, iControl can detect the discontinuity, interrupt the process immediately and inform the relevant team member.

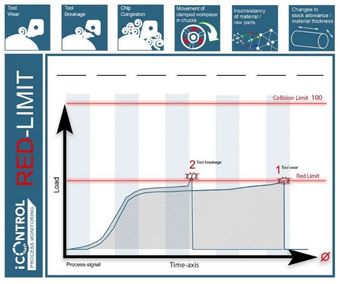

The maximum loads on the individual axes and spindles – known as "red limits" – can be freely selected anywhere up to the collision limit. This means that, for each operation, there is a pre-set percentage of the maximum permissible load for each axis or spindle. If no limit is selected, the collision limit set at the factory will apply automatically.

Smart aid

The process signal from a complete machining sequence can be recorded using a teach-in cut. The allocation of upper and lower process limits defines the tolerance band within which the process signal must remain during machining. If these limits are violated, the machine will stop. It is also possible to select a pre-warning limit, otherwise known as a "yellow limit." If this limit is reached, the machine will not stop immediately. Instead, a message will be generated to enable the operator to respond in good time, i.e. before another limit is reached. This primarily serves to ensure uninterrupted operation and makes it possible to replace worn tools even if they have yet to reach the end of their (theoretical) tool life. Typically, the collision limits set at the factory will always automatically limit any process-related forces to a level that is safe for the machine.

Nevertheless, there are often applications where the stability of the workpieces, the clamping devices or the required tools simply does not permit large machining forces. The "red limit" can help in these cases in particular because the machine will stop immediately – even if the limit is exceeded for only the briefest of moments. However, the "red limit" also serves to detect tool breakage, chip jams or blanks that are too large and can always be activated in the background so to speak.

Essential to automated production

The "iControl" process monitoring system is typically characterised by its extremely high sensitivity and reliability. The signal value for process monitoring is derived directly from the drive torques of the NC axes and spindles. A special algorithm eliminates friction and acceleration forces, making it possible to analyse the process signals with ultra precision. "iControl" provides essential services specifically for automation and series production. However, making the machining process fully transparent is also beneficial for complex internal machining tasks. As the saying goes, once you've tried it, there's no going back.

The advantages at a glance:

- Greater process reliability thanks to continuous monitoring of machining operations

- Protects the machine against damage

- Increased productivity and workpiece quality

- Tool cost savings and better utilisation of the tool life due to wear monitoring

- Better utilisation of the machine as process signals are shown on the display

- Reduced workload for operators

- Integration of sensored tools

- Maximum sensitivity thanks to teach-in technology

- Option to perform monitoring without teach-in cut

- Optimum monitoring of machining processes with different cutting depths thanks to adaptive limits

- Option for early detection of machine wear by using myWFL Condition Monitoring