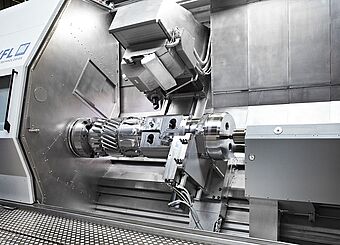

Limitless complete machining with M120 MILLTURN / 3,000mm

At IMTS 2018, which takes place from September 10 to 15, WFL proves to be the leader in technologies once again. The Austrian company presents its tremendous progress by dealing with different topics concerning Industry 4.0, such as the new WFL Data Analyzer or the brand new version of CrashGuard Studio featuring programming and simulation. But that is not the end of the story. The actual highlight of the show is the presentation of the M120 MILLTURN.

The M120 MILLTURN convinces customers with machining lengths from 78 to 315 inches and a swing of up to 48 inches. Along with superior power ranges (up to 168 hp) and torque values (up to 8680 ft lb) of the main spindle, enormous feed rates on all axes make for impressive dynamics and utmost productivity. The 74 hp direct-driven milling spindle guarantees maximum power even at low speed rates – a huge advantage when using large drills and milling cutters. The phenomenal clamping forces of the B-axis allow for the use of damped boring bars with a diameter-length ratio of up to 1:14. A separate pick-up magazine is available optionally for heavy ID-machining tools of up to 5 ft length and 320 lb weight. On top of that WFL offers another fully automated solution for the use of tools up to 8 ft. Turning, boring, milling, gear cutting, deep-hole boring as well as ID-machining is possible in any angle.

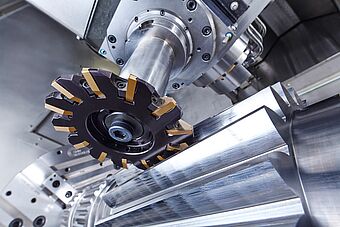

The spectrum of gear cutting – FLANX

In order to meet increasing quality requirements, profile correctness and the search for flexible machining solutions, the topic “FLANX gearing solutions” has been worked on anew. Due to high material removal rates, flexibility in machining and in-process measurement, WFL’s MILLTURNs are excellently suited for the manufacturing of gears, pinions and gear cutting of shafts. Intelligent software solutions supporting various machining operations allow for efficient and easy manufacturing of the required gearings.

„The demanding expectations in the area of gear production claim the highest quality and profile correctness combined with reliable and flexible solutions (especially in the manufacturing area of small and medium sized batches).” This is the answer from Kenneth Sundberg, General Manager „After Market Sales“ bei WFL Millturn Technologies, as we talked with him about his passion for gearing solutions. Even though machining operations on traditional gear cutting machines is well-established, there is a new trend in this business. Become differentiated with the 5 axis complete machining centers from WFL Millturn Technologies.

Competitive pressure is in the air. Constantly changing customer requirements set a new framework in the area of gear production. It gets more and more evident that the times when the complex methods of gear production were reserved only for niche markets or specialists come to an end. The trend towards shorter lead times and consequently an increased production output needs a strategic rethinking of gear manufacturers as an economic method of production is only possible when all gears engage seamlessly. To play in the top league of metal processing, manufacturer have to be able to deliver both: highest quality and flawless results. Thanks to the 5 axis complete machining centers and the advanced WFL technology “flawless” is an achievable goal.

The manufacturing process of gearing solutions is based on stable processes. Machining operations are affected even by the smallest changes. Therefore, the perfect combination of machining center, process data, clamping tools and measurement systems are significant. Thanks to the latest measure and scanning technology, inflexible manufacturing methods with customized high-speed steel (HSS) tools fall into oblivion. In return, the importance of automatic quality inspection increases rapidly. A precise interpretation of the evaluated data enables the operator to take eventual corrective measures. When it comes to the competitive production of a single gear piece or pinion it is essential to have individual and flexible control over the production system.

Focus on Industry 4.0

The enormous variety in the field of industrial production enables each and every customer to prepare perfectly for the automated future. The WFL Data Analyzer allows a perfect overview over the whole manufacturing chain. The calculation of essential key figures, such as machine and process data, as well as productivity and availability data give crucial impetus for optimising the production.

Moreover, an upgrade of CrashGuard Studio, an in-house simulation and programming software, will be presented. The software allows for pre-verification of NC programs on the computer and comfortable programming using a programming editor. The newest innovation consists in the possibility of programming channel geometries for worms.