Schaeffler Aerospace: Precision, integration and innovative strength – complete machining with WFL MILLTURN for the most stringent requirements in the aerospace industry

Schaeffler Aerospace Germany GmbH & Co. KG based in Schweinfurt is a subsidiary of Schaeffler Technologies AG & Co. KG. With around 600 employees, the company is a leading developer and manufacturer of high-precision roller bearing systems for the aerospace industry. In addition to manufacturing, the company specialises in developing, designing and rigorous testing complex bearing systems, each one tailored to the unique demands of its intended application. As well as producing new items, Schaeffler Aerospace also offers a comprehensive MRO programme to sustainably recondition bearings and thus ensure long-term supply reliability. To master all these requirements with precision, the company has purchased a total of six WFL MILLTURNs in recent years. The latest addition is an M50 MILLTURN with automation cell.

Roller bearings used in the aerospace sector must be able to withstand extreme temperatures, challenging load profiles and high speeds. The industry also requires over 70 years of traceability and documentation with the highest levels of component quality and reliability. What's more, production of the bearings must be guaranteed over the entire usage cycle spanning several decades.

At Schaeffler Aerospace, 75% of bearing components are used in engines for passenger and military aircraft and 25% are used in helicopters and aerospace applications. The materials used, such as Inconel 718, case-hardened steel M50Nil or Cronidur 30, are extremely tough and difficult to machine. At the same time, the tightest of tolerances must be met during machining and thin-walled geometries created without causing any microstructural damage.

Efficiency through complete machining

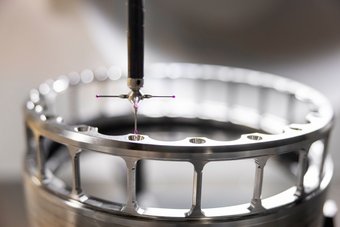

Schaeffler Aerospace has been using WFL MILLTURN machines to meet these requirements since 2006. Prior to the purchase of these machines, many machining steps were carried out separately on classic 2-axis turning and 5-axis milling machines. Thanks to the MILLTURN, the company was able to achieve process-integrated complete machining for the first time. Machining steps such as turning, milling, drilling or measuring are now carried out on a single system, which reduces set-up times, prevents reclamping errors and improves the machining quality. In the case of average batch sizes between 15 and 50 pieces, the number of set-up processes plays a decisive role. "One of the particular advantages of the MILLTURN machines is the integrated B-axis. Thanks to swivelling tool positioning, complex component geometries can be created with a small number of tools in just one clamping operation," explains Thomas Memmel, Head of Technology Development at Schaeffler Aerospace.

Despite occasionally longer overall cycle times, combining the machining operations is economically advantageous, especially in regard to autonomous shifts or multiple machine operation.

The MILLTURN machines also offer convenient CNC programming and are perfectly integrated in CAM environments, which means that machining strategies can be implemented efficiently alongside rapid adjustments and optimum planning of the machining steps. At Schaeffler Aerospace, this has reduced the programming time and maximised process stability, even for small batch sizes and variable geometries.

The decision to work with WFL was mainly due to the machines' characteristic properties of maximum rigidity thanks to the slant bed design as well as a B-axis mounted on a double-bearing. As a result of the many years of positive experience with this machine concept and the highly skilled service team, Schaeffler Aerospace has been using WFL machines for almost two decades now.

Another key factor is WFL's range of complete solutions. "It's a huge advantage for us to be able to procure the machine and automation technology from a single supplier," says Thomas Memmel.

Fields of application

The finished bearings can be found in modern Rolls-Royce aircraft engines such as the Trent 1000, Trent XWB or Pearl 10X models used in the 787 Dreamliner and A350 airliners or business jets. Components from Schaeffler Aerospace are also installed in engines for the new A320neo and 737MAX short and medium-haul planes. These engine programmes are of central importance to the aviation industry.

Helicopter manufacturers also put their trust in bearing solutions from Schaeffler Aerospace. These bearings feature in gear units, transmission shafts and swashplates, where they ensure the ultimate in smooth running properties and reliability – even under changing loads and difficult climatic conditions.

Another outstanding area of application lies in aerospace. Schaeffler bearings are used, for example, in the turbopumps of the RS-25 engine – the high-performance engine used in the first stage of NASA's SLS (Space Launch System). These bearings must withstand incredible speeds and operate in unique environmental conditions. The bearings are lubricated with liquid water and oxygen at operating temperatures below -200°C: requirements that can only be met by absolutely reliable and precisely manufactured components.

The process reliability is supported by state-of-the-art measurement technology within the M50 MILLTURN, such as integrated scanning measuring probes, which enable exact process monitoring during machining. The tolerances required are in the range of 20 µm for turning and up to 10 µm for milling – values which can only be achieved with consistent process control.

Digitalisation, automation and sustainability

Schaeffler Aerospace got on board with digitalisation at an early stage to make processes more efficient and to ensure the high level of traceability that is essential for the aviation sector. "We develop our own software applications to gradually move towards a paperless production model and to develop a more consistent process chain. This proactive approach shows that we anticipate and set trends rather than merely respond to them," explains Thomas Memmel.

When it comes to metal cutting, Schaeffler Aerospace relies on connectivity to drive process optimisation or extend service life using data. Particularly noteworthy is the company's focus on the quality of high-performance components, which is always the utmost priority. These measures demonstrate a deep understanding of the industry and a clear alignment with future-proof, high-quality and production-related processes.

The company is also making headway in regard to automation. Thanks to robot-assisted loading and a largely unmanned third shift – including at the weekend – the company is able to compensate for shortages in skilled workers and reduce costs. The challenge lies in the sensitivity and high quality of the components; loading errors must be reliably detected and prevented. This requires intelligent process monitoring using sophisticated sensor systems, which have been developed by WFL itself.

The rapid pace of technological development means Schaeffler Aerospace has to be clever about selecting and integrating megatrends. In the field of automation, it is clear that there are challenges in regard to small batch sizes and changing geometries. Nonetheless, the company places great value on programming systems quickly and minimising set-up times during type changeovers. Michael Both, Head of Industrial Engineering Aerospace, emphasises the decisive role of automated and complex solutions when it comes to ensuring a competitive edge in a high-wage economy such as Germany. Efficiency and precision are essential in the aerospace industry, which is why advanced technology is used to reduce errors and increase production quality.

As a leading motion technology company, Schaeffler regards sustainability as a holistic, overarching topic and assumes ecological and social responsibility throughout the entire value chain. In order to put its ambitious sustainability strategy into practice, the company relies on collaboration – with customers and suppliers, executives and staff as well as other stakeholders. Technology, innovation and the pioneering spirit that has shaped the Schaeffler Group for decades all play a key role here.

"Thanks to WFL's MILLTURN machines, we have been able to keep improving our processes for over 15 years and meet increasing customer requirements," emphasises Thomas Memmel.

The use of MILLTURN technology is a strategic key for Schaeffler Aerospace in meeting stringent quality requirements – both today and tomorrow. Combined with digitalisation, automation and sustainability, the company continues in its role as a reliable and innovative partner to the global aerospace industry.