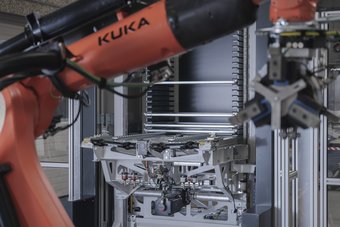

The storage tower – for space-saving intermediate storage with added value

Not only do clean, tidy production halls look modern, they also increase motivation and create an environment where people enjoy working. This insight has become widely accepted, but there are still some places where it is yet to be applied. The WFL storage tower represents a huge step forward for one such area in the production process.

In addition to clearing away the raw material and finished parts to free up valuable production space, it can also provide sufficient storage capacity for long unmanned production phases when combined with WFL automation.

Although the components are physically relocated, transparency is maintained by intelligent cell management. This cannot be achieved by conventional means and in some cases extends far beyond what is usually possible. Thanks to interfaces to the ODA and customer's ERP systems, the stock and order overview can be integrated into the entire higher-level production planning system and not just the cell itself.

WFL automation cells can be equipped with numerous innovative features, meaning they are not limited to large-series production and can also be used to produce small series and single parts economically, automatically and highly efficiently in unmanned shifts.

Universal pallets or bin picking solutions significantly reduce the tooling times and play a key role in increasing efficiency and lowering costs.

Jaw/collet changing systems and changing systems for gripper and gripper fingers allow for self-equipping systems to be set up.

As the interchangeable parts can also be stored away again in the storage system and the software manages the resources, this results in highly flexible production cells.

Operators are well supported with a user-friendly, intuitive user interface along with a continuously available system status display. This enables precise, real-time range analysis incorporating all relevant variables: the current stock of raw materials, the release status, the production orders, the availability of necessary clamping devices and interchangeable parts as well as the remaining tool life.

But it's not the end of the story for the cell itself!

Not only does the system feature software interfaces, it is also increasingly being combined with AGV connections to suit customer requirements.

Facts about the tower model on display at EMO

- Shelf size 600 x 800 mm

- Shelf load max. 250 kg

- Tower height 2.9 m

- Loading via side drawer

The essentials

- Tower solutions enable space-saving cell solutions with high storage capacity

- Modular tower concept à Equipment according to individual requirements (height, shelf size/load capacity, control panel design, etc.)

- Tower can be loaded manually or in combination with AGVs

- Intuitive user interface with clear display of tower occupancy

- Suitable for workpieces, tools, and clamping devices

We look forward to seeing you there!

Hall: 13 | Stand: A50