Strong presence at EMO Hanover: World premiere of the M70 MILLTURN, innovations, and valuable contacts

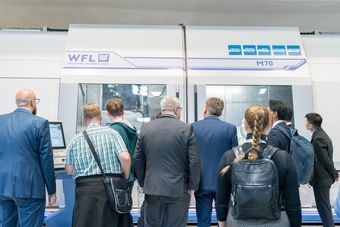

WFL Millturn Technologies draws a positive conclusion from this year's EMO Hannover. The leading international trade fair for metalworking provided the ideal stage to showcase technological innovations and, at the same time, intensify personal exchanges with customers, partners, and industry professionals. With two MILLTURNs on display at its booth, WFL impressed numerous visitors from September 22 to 26 – above all with the world premiere of the new M70 MILLTURN, which proved to be a real crowd-puller.

Right from the first day of the trade fair, the M70 MILLTURN proved to be a crowd-puller. The machine impresses with its high standards of productivity and precision and attracted great interest from visitors from Germany and abroad. “The response to the M70 MILLTURN was first-class,” emphasizes the WFL management by Stefan Hackl (CCO & CFO), Günther Mayr (CTO & CSO) and Franz Schön (COO). The trio adds: “Many visitors took the opportunity to experience the new product live and talk to our experts. This direct feedback is extremely valuable to us."

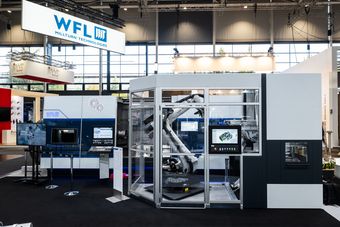

Another highlight was the storage tower. It illustrates how efficiently, and space-savingly modern manufacturing solutions can be implemented. The interplay of machines, automation, and intelligent storage was praised by many trade visitors as forward-looking.

In addition to the technical highlights, the personal exchanges were also impressive: Customers, interested parties, and partners took the opportunity to discuss industry trends, solutions, and future topics. “Once again, EMO provided us with the ideal platform to cultivate existing partnerships and establish numerous new contacts,” emphasizes Head of Sales, Christian Jagersberger. WFL can look back on a successful trade fair participation and is confident that it will be able to further expand the contacts and momentum gained at EMO in the coming months.

Spotlight on our M70 MILLTURN

The M70 is a multifunctional turning, drilling, and milling center of the latest generation. It combines the capabilities of a powerful lathe, a high-precision 5-axis machining center, and—depending on requirements—a gear cutting or deep drilling machine. What makes it special is that all machining steps can be performed in a single setup. This reduces non-productive time, increases accuracy, and makes the M70 a truly complete solution for complex components.

The M70 is designed for very large and heavy workpieces. It can accommodate parts with a center distance of up to 8000 mm, a maximum swing diameter of 850 mm, and a workpiece weight of up to 5.5 tons. For comparison: 5.5 tons is roughly equivalent to the weight of a full-grown elephant. This means that the machine covers an enormously wide range – from long shafts and solid housings to complex chuck parts.

The main spindle delivers up to 5,860 Newton meters of torque and reaches speeds of up to 2,500 revolutions per minute. This torque is roughly equivalent to the combined power of around 20 modern car engines. The robust cast spindle housing, stable spindle bearing and backlash-free holding brake guarantee maximum rigidity – even when machining difficult-to-cut materials such as Inconel or titanium.

The milling unit delivers up to 58 kilowatts, reaches 8,000 revolutions per minute, and has a maximum torque of 640 Newton meters. Particularly noteworthy is the interpolatable B-axis with a swivel range of 220 degrees and a holding torque of 15,000 Newton meters. This makes the M70 suitable for long and heavy boring bars, which are held in a stable prism interface. The milling spindle is also equipped with an internal coolant supply of up to 200 bar, which guarantees excellent machining conditions even for deep drilling.

Despite its dimensions, the M70 MILLTURN achieves maximum precision. This is achieved on the one hand by high-resolution direct measuring systems in all axes and a structurally optimized machine frame made of solid gray cast iron with integrated vibration damping. On the other hand, it is achieved by intelligent measuring technologies: With integrated measuring probes, workpieces can be measured directly in the working area and deviations can be corrected automatically. In addition, the iControl software ensures continuous cutting force monitoring, enabling maximum process reliability even in unmanned production.

The M70 is fully digitally networked. CrashGuard protects the machine from collisions in real time. CrashGuard Studio also enables offline simulation directly from the NC program. Millturn PRO allows programs to be created graphically and interactively. And the myWFL cockpit provides customers with functions such as energy consumption analysis, condition monitoring, and health checks. This makes the M70 fit for Industry 4.0 and future-proof manufacturing processes.

In addition, the MILLTURN is designed for continuous 24/7 production. The WFL machine can be combined with robots, gantry loaders, or complete manufacturing cells. WFL offers customized automation solutions – from workpiece handling and tool supply to automatic changing of chucks, tailstocks, or even prismatic tools. This bridges shift breaks, increases productivity, and significantly reduces unit costs.

In summary, the M70 MILLTURN is particularly interesting for WFL customers due to its maximum flexibility in production. Whether small batch sizes or large series, simple turned parts or complex components such as crankshafts – the M70 covers everything in a single machine. It reduces changeovers, shortens throughput times and at the same time increases process reliability. For WFL customers, this means higher productivity, lower costs and a sustainable investment in the future.

Storage Tower

In addition to the M70 MILLTURN, visitors had the opportunity to learn about the automation solution using a storage tower on the proven M20 MILLTURN. With the storage tower, the raw material and finished parts disappear from the production area, resulting in a clean and tidy production hall. With WFL automation, a long-unmanned production phase can also be provided.

Despite the physical removal of the components, transparency is maintained through intelligent cell management, which cannot be achieved in the conventional way and in fact goes far beyond it: interfaces to PDA and customer ERP systems allow the inventory and order overview to be integrated not only into the cell itself, but also into the entire higher-level production planning.

WFL automation cells can be equipped with numerous innovative features, so that their use is not limited to large-scale production but also allows small series up to individual parts to be produced economically, automatically, and highly productively in unmanned shifts.

The operator is comprehensively supported by a user-friendly, intuitively designed user interface and a continuously available system status display. This enables precise range analysis in real time, taking into account all relevant influencing factors: the current stock of raw materials, the release status, the production orders, the availability of the necessary clamping devices and replacement parts, and the remaining tool life.

The system not only has software interfaces, but is also increasingly being combined with AGV connections, depending on customer requirements.