The spirit of innovation at its peak

Some fields, a small municipal road and a sign reading “Business Park Holzhausen”. Nothing suggests that we are about to find high-tech potential in this small town near to the airport in Linz. Peak Technology was founded in 2007 by Dieter Grebner. The company not only provides Formula 1, but also the aerospace industry with complex and ultra-light carbon fibre composites.

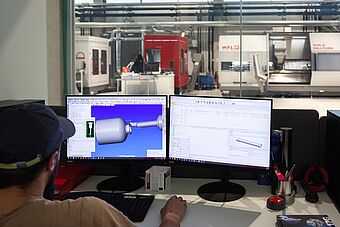

Electrification of aviation and autonomous flying planes are omnipresent topics at Peak Technology. 120 employees manufacture parts for the aircrafts of the future. Matthias Lechner, Managing Director Technics, talks about the company’s visionary projects. Peak Technology is already wondering how air mobility will look like in 10 or 20 years, but wants to fly even higher. They wrap high-pressure accumulators, fuse bodies and structure components with carbon fibres for aerospace projects. By contrast, their ultra-light high-pressure accumulators, which are capable of withstanding pressures up to 700 bars, seem to be more of a standard repertoire. Moreover, Peak’s portfolio comprises engine components for Formula 1 racing cars. Compared to all these science fiction projects, however, it seems as if we were talking about some parts of a simple steam engine. Despite their high-tech requirements, Peak Technology thinks of themselves as a manufacture because fibre composite technology involves lots of complex manual processes. The company combines traditional craftsmanship with high-tech manufacturing. Since 2019, Peak uses a M35-G MILLTURN by WFL for CNC manufacturing.

Peak decided to expand its ultramodern machinery in order to meet future requirements and improve CNC manufacturing. Before they bought the MILLTURN, the parts had to be machined separately on turning and milling machines. Matthias Lechner states, “We wanted to reduce loading and unloading to an absolute minimum and simplify manufacturing planning. Furthermore, our customers have high demands on tolerances and we knew that we would have to opt for complete machining with as few clampings as possible to meet their requirements.” Finally, free form surfaces with tolerances of about 0.005 mm have to be maintained reliably. These specifications require air conditioning of the entire production area as well as high-quality measuring technology. The batch sizes of individual orders vary between 10 and 30 parts. “Our customers ask for just-in-time delivery. They don’t want to receive all parts at once. For this reason, even for “series” of 10 parts just one single part is being manufactured at a time each week. At the moment, we use the MILLTURN to manufacture 10 to 15 different parts and the number is rising daily.” explains Lechner. “At Peak Technology we process metallic materials such as titanium, high-strength steels and aluminium as well as carbon fibre components.” says Christian Brunner, Team Leader of the Machining Department. “This would be so much easier, if we only had a MILLTURN.” he is said to have sighed formerly when manufacturing complex parts.

The time had finally come when the company expanded in 2018. Matthias Lechner remembers, “We visited all competitors in the market in their factories. What we liked best about WFL’s MILLTURN was the slant bed construction and its massive casted bed. To put it in other words: a very stiff machine. Eventually, the proximity to WFL was important to us as well. We didn’t want to work together with distributors as many other international companies do.” Brunner and Lechner agree, “As we are using very small tools, a spindle speed of 16000 min-1 is crucial. The standard version with 12000 min-1 wasn’t sufficient. Fortunately, WFL had already been testing a counter spindle version with 16000 min-1 for some time and one of their customers had successfully implemented one too. Speed in combination with high stability and precision is actually much more important to us than machining volume and power.” Especially for components with very small radii, tiny ball cutters are applied. The parts are clamped in a three-jaw chuck with quick jaw change. A clamping system by Hainbuch, which is clamped in the power chuck, is currently used for testing. In some instances the work pieces are clamped internally by means of a clamping mandrel. If the work pieces are clamped in the chuck, the clamping pressures are freely programmable and can be adjusted in small steps during one clamping under NC control. There is no need to open the chuck when adjusting the pressure by programme. All of the above mentioned features are key for manufacturing thinwalled work pieces. “We’re gaining more and more experience each and every day. Even though we do know a lot about 5-axis milling, we have to slowly approach the new possibilities that our MILLTURN shows us over and over again. It’s a completely different dimension of complexity. We’re continually milling in 5 axis on the MILLTURN. It works properly and delivers exact results. We are highly satisfied and would soon like to use the MILLTURN not only for turning, boring and milling, but also for gear cutting.” Lechner summarises the experience with the new machine.

Regarding software technology, however, there was a tough nut to crack for WFL beforehand: the zero point in the CAM system and the actual position in the machine should be compared automatically by means of Form Inspect by M&H. A probe measures the dimensions of the clamped raw part. By using a specific software solution, the machining zero point may thus be corrected according to the actual position of the raw part directly at the control. If the position or form of the raw part does not correspond to the CAD exactly, the ideal position is determined by means of a best-fit calculation and the coordinate system of the CNC programme is shifted or turned into the ideal position in order to reach a constant allowance of the entire raw part. This, in turn, ensures constant machining allowances and continuous cutting conditions throughout the entire machining process. WFL and M&H worked closely together in order to adjust the system. It was thoroughly tested by WFL afterwards and fully functional immediately after the delivery of the machine.

Peak uses the tool system Capto C6 in their MILLTURN. Stability was again the key factor. “We talked to different industry experts and realised that Capto totally meets our requirements”, says Matthias Lechner about the precise analysis carried out previous to the investment. Tools are set by means of a pre-setting device. The tool data is stored on a chip at the tool itself. When loading the tool into the machine, the data is automatically transferred to the control and stored in the tool management. Peak aims to leave all tools they need to process their orders in the machine. The current tool magazine of the M35-G MILLTURN comprises 120 tool stations and has thus even enough vacant positions for twin tools.

It’s all about precision. And Peak is not prepared to compromise over that. The machine features glass scales in all linear axes. Even though the MILLTURN was within all tolerance values at acceptance, Peak still asked for more precision and WFL’s experts made sure to tease out each and every μ. Furthermore, the machine was equipped with a special extraction system which serves to extract oil mist as well as the dust which is generated when machining carbon fibre components. When it comes to connectivity, Peak is at the highest level too. All machines are connected to the ERP system and transmit running times as well as downtimes in real time. Moreover, Peak uses the IoT solution MindSphere by Siemens. It allows WFL to analyse sensor data such as the temperature of the milling unit upon Peak’s request. WFL can thus react to potential future service requirements at an early stage.

Peak explicitly demands that all CNC machines should be programmable with CAM systems. Programming is carried out by means of the CAD/CAM system hyperMill. Complex parts require two or three days of programming effort, while simpler parts can be manufactured within a few hours. In addition, WFL’s software solution CrashGuard Studio is used for various simulations previous to machining and in particular to simulate the transfer of the work piece to the counter spindle because this is not possible with CAD/CAM systems yet.

In order to protect the machine, valuable components and tools, Peaks uses WFL’s anti-collision system CrashGuard. Peak’s manufacturing experts declare unanimously: “Crash-Guard is essential considering our requirements. The investment already pays off, if the software prevents a collision.”