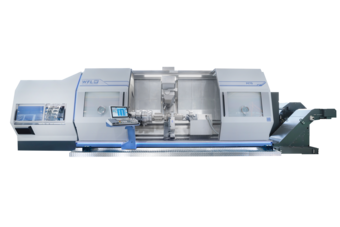

Unfolds new possibilities: Precision at its strongest with the new M70 MILLTURN

The new M70 MILLTURN, the latest addition to the WFL product family, is ideal for applications which require the ultimate in productivity and precision.

The M70 MILLTURN impresses with a sophisticated working area concept for working lengths of up to 8000 mm and for a swing diameter of up to 850 mm. Thanks to the well-known and extensive WFL modular system, it offers enormous variety and can be tailored to each customer's requirements.

In addition, the new M70 MILLTURN offers optimum stability and geometry for maximum precision, reliable machining thanks to high pull-in forces at the tool interface, and a wide range of additional options for highly productive deep-hole drilling processes and special technologies. With the capability to machine workpieces weighing up to 5,000 kg, the MILLTURN is ideal for heavy-duty applications.

The M70 MILLTURN features the familiar, reliable disc tool magazine or chain magazine with up to 200 tool stations and capacity for tools weighing up to 35 kg with a maximum length of 900 mm. In addition to automatic tool changes, the set-up process can also take place in parallel to the machining time. This allows the magazine to be tooled for different orders without any loss of time.

Two magazine variants are also available for heavy special tools weighing up to 200 kg each.

The M70 MILLTURN also features extremely reliable main and milling spindle drives, delivering maximum precision and advantageous versatility for different customer needs.

The optional WFL prismatic tool interface by means of a large prismatic tool accommodation enables the use of tools which exceed the maximum dimensions of standard tools.

For the M70 MILLTURN with its large drilling and turning tools, high torque and high performance are extremely important in maximising the performance of the tools.

Enhanced performance thanks to WFL prismatic tool

Specially developed tools which have been designed to work seamlessly with the MILLTURN enable precision machining of complex workpieces. As hard to access machining areas often require the use of long special tools, the use of robust prismatic clamp holders means that boring bars, solid drills, and angular heads can be attached to the turning-boring-milling unit in a highly stable manner. The WFL system boring bar enables automatic changeover of the cutting heads. Two types of magazine are available to provide automatic handling of heavy internal machining tools. These innovative tool solutions enable users to maximise the machine's full performance potential.

Prismatic tool magazine

- Number of storage locations: 15

- Max. tool length: 2500 mm

- Max. tool weight: 200 kg

- Endless variety of technological applications (bottle boring tool, grinding attachment head, NC facing head, etc.)

Pick-up magazine

- Separate tool magazine above the headstock

- 3 magazine places

- Max. tool length: 1780 mm

- Max. tool weight: 200 kg

Technological superiority for the highest demands

Thanks to innovative in-process measurements, complex measuring tasks can be mastered with simple programming. This enables maximum manufacturing precision to also be achieved with the tightest dimensional and positional tolerances. Analyses can be carried out and measuring protocols can be created at any time.

Another key advantage can be found in regard to the coolant pressure. Thanks to targeted chip breakage optimisation and the use of high-pressure coolant (HPC) of up to 150 bar, the machining costs can be noticeably reduced. What's more, ultra-high pressure coolant (UHPC) ensures even greater efficiency, lower tool costs and improved process reliability during machining.

Workpiece transfer is also optimal with the M70-G MILLTURN counter spindle machine. The counter spindle with tailstock and synchronous spindle function combined with the powerful motor spindle and a drive ensure reliable machining processes and maximum machining performance.

Intelligent tool management makes operation even easier. It offers convenient software functions, straightforward and logical menu navigation along with automatic tool correctors, which are automatically converted by the control system and ensure efficient operation.