WFL Automation Solutions: Intelligent automation as the key to competitive manufacturing

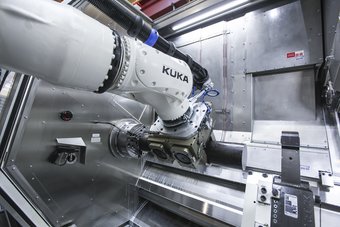

The demands placed on modern manufacturing companies are increasing rapidly: greater flexibility, consistent process reliability, and maximum output are no longer optional extras, but requirement. WFL Automation Solutions has been meeting these challenges for years with intelligent, tailor-made automation concepts — consistently positioning itself as a solution provider for the manufacturing industry of tomorrow.

Rising personnel costs, increasing international competitive pressure, and the demand to operate machines efficiently around the clock make automation indispensable for many companies across all industries. At the same time, the world of work is changing: night and weekend work are becoming less attractive, while expectations for productivity and delivery capabilities continue to grow. Automation closes this gap – and enables cost-effective 24/7 production.

From machine manufacturer to solutions provider

Today's customers expect much more than a single machine. They want turnkey production systems that map processes holistically and secure long-term competitive advantages. WFL recognized this change early on and therefore attaches great importance to well-thought-out automation concepts – both for new systems and for the expansion of existing systems.

The goal is clearly defined: to reduce production costs, increase output, and secure jobs at the same time. Because automation does not mean staff cuts, but rather qualification. Experience shows that the requirement profile is changing – toward skilled workers who understand, control, and optimize complex turnkey processes.

Customized solutions instead of standard concepts

The focus of every automation solution is on the customer—and their actual requirements. “Customers usually know what they want, but not always what they really need,” explains Manfred Fahrion, Key Account Manager at WFL Automation Solutions. Only through intensive dialogue can we determine which automation concept will be efficient in the long term. Customers are often surprised by the potential that modern automation offers today – far beyond simple loading and unloading.

That's why our solutions are always developed in close cooperation with the customer. The experience and expertise of the future operators are also incorporated into the development. This allows different levels of complexity to be realized – always according to the principle: Keep it simple. Processes are simplified, productivity is increased, and complexity is reduced in a targeted manner.

A structured path to turnkey automation

It takes around twelve months from order placement to commissioning at WFL. After the order is received, all requirements are precisely defined in a detailed design phase lasting two to three months. This is followed by the implementation and production phase at the St. Konrad plant. The automation system is then installed, tested, and approved at WFL in Linz. After successful approval, it is transported to the customer and set up and finally commissioned on site.

Limits? None so far.

“To date, we have not encountered any limits to automation in any of our projects,” says Manfred Fahrion. Almost everything required for the respective application is technically feasible. Although there are still physical limits in robotics — for example, with very high payloads or limited space—WFL always works with the customer to find alternative solutions that are optimally tailored to the respective production environment.

Intelligent communication and predictive data usage

Intelligent communication is a key element of WFL automation. This takes place on three levels: fixed communication, basic communication, and a higher-level host system for comprehensive data acquisition. Not only is the status of the machine monitored, but predictive planning is also carried out.

The system checks, for example, the tool magazine, tool availability, and remaining service life, and compares this with the NC program. Only when all requirements are met is a workpiece automatically loaded. Otherwise, the next component is selected from the queue. After machining, the robot takes over unloading. Depending on the signal sent by the machine, the robot or gantry places the finished workpiece in the storage area or rejects it – with optional manual rechecking by the operator.

More than technology: experience, process knowledge, and future-proofing

WFL not only supplies automation technology, but also a holistic concept. This includes proven processes, in-depth experience from numerous projects, and expertise in how machines and automation interact optimally. The result is solutions that provide lasting relief, reduce production costs, and ensure long-term competitiveness.

An additional effect: modern automation is not only efficient but also makes a strong visual statement. State-of-the-art technology in your own production hall inspires employees, customers, and potential skilled workers alike – and impressively demonstrates that your company is moving with the times.