WFL Heavyweight Performance

Machining large and very heavy components is often an extremely complex undertaking that involves considerable costs. Not so with „WFL Heavyweight Performance“. Here, process reliability and, above all, time savings, take centre stage.

Higher, faster, farther – all this is great, but now „longer, wider and heavier“ is also possible. Industrial requirements are becoming increasingly stringent. This is where „Heavyweight complete machining“ from WFL comes into play.

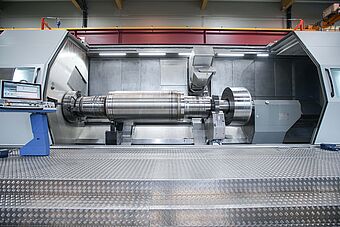

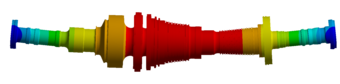

Special requirements call for special measures. To meet these requirements, WFL can realise a workpiece weight of up to 60 tonnes. What‘s extraordinary about this is that heavy components such as these can be machined with a single clamping procedure. A MILLTURN can handle high-strength steel or HRSA (Heat-Resistant Super Alloy) material with ease. This no longer requires special machines, as was previously the case in multistep production processes. The use of special in-process measurement methods and temperature compensation corrects any workpiece displacement, thereby increasing the overall machining quality. With the WFL measurement methods, a workpiece can be produced with maximum precision even under unfavourable production conditions (e.g. external influences such as temperature changes during the production process).

Tedious workpiece changeover processes or clamping device adjustments are now a thing of the past, as both of these tasks can be significantly reduced with a MILLTURN. With the most diverse range of machine assemblies from M100 to M200, a perfectly harmonised machine can be realised to suit any customer requirement.

Examples of parts that can be produced:

- Gas turbines

- Steam turbines

- Components for wind power plants

- Rollers

- Crankshafts

- Gear components

- Shaft parts

Advantages

- Reduced set-up time

- Years of experience in optimum complete machining methods incl. distortion-free and secure workpiece clamping

- Advance FEM calculations to ensure the correct design of the workpiece clamping

- Optimum workpiece support (roller or hydrostatic steady rest)

- Minimised production errors

- Optimum machining quality and production

- Extremely stable machine construction

- Closed working area for machining with a high coolant pressure and flow rate as well as chip removal for automatic extraction

- Excellent ergonomics with very good workpiece accessibility in the working area

- Flexible measurement technologies (variable cycles)

- CrashGuard Studio for programme testing

- Production support from WFL technicians

- Uncomplicated design and support