WFL looks back on 30 years of success

30 years of WFL and 40 years of MILLTURN: two anniversaries that deserve special attention. Last year, WFL proudly celebrated its 30th anniversary. From an initial group of 12, the team has grown to more than 500 employees over the years. Through cohesion and the common goal to be "best in complete machining", WFL has always been on the rise in recent decades.

The world's first complete machining centre, a Millturn WNC, has already been developed back in 1982. At that time, machine tool production was still part of VOEST-ALPINE. In 1993, the Werkzeugmaschinenfabrik Linz (WFL) emerged as an independent company and concentrated on the manufacture of turning-boring-milling centres called the MILLTURN. WFL was taken over by the Autania Group at that time.

Focussing on complete machining since 1983, WFL is the technology leader in the field of metal-cutting manufacturing machines. The combination of different manufacturing technologies such as turning, milling, boring, or grinding in one machine tool, is referred to as complete machining. The concept “clamp once - machine complete” brings significant economic and production-related advantages.

Whether high-tech automation solutions or intelligent data utilisation - WFL combines the latest technologies with proven expertise. Decades of experience in complete machining are the company’s decisive feature. A reliably high quality of the machines and the continuous development of technologies in complete machining are the quintessence.

The birth of the MILLTURN

Machine tool and lathe construction was initially still a small division of VOEST-ALPINE and was founded after World War II. As there were no machine tools on the market, the company decided to build these machines itself. In the 1950s, they were very successful and technically absolutely on trend. For further development, the VOEST-ALPINE drew on the expertise of Weipert in 1974, which had already made a name for itself in machine tool construction at the time. Their technical know-how was state of the art and was therefore taken over by VOEST-ALPINE, as were the design engineers.

In the mid-1980s, VOEST-ALPINE had to adapt to a more globalised, specialised world. Due to the networking of production sites throughout Europe, the production of parts had to be increasingly outsourced, which ultimately led to the restructuring of the company. The technology of complete machining in turning-boring-milling centres at VOEST-ALPINE Maschinenbau and VOEST-ALPINE Steinel gained worldwide recognition at that time. There were machines with robots, which were called AUTO-MILLTURN. They also had to think of a name for the complete machining centre, which was finally called the “MILLTURN”. That was in 1983.

Associated challenges

One of the technical difficulties was to integrate a small machining centre into the lathe. The engineers developed a double slide and a standard tool turret for turning on one side and a separate, small machining centre with an internal, coupled tool magazine with steep taper tools, which were still standard for turning and milling, on the second slide. A private company would never have dared to take this step at the time and a market analysis of a machine that did not yet exist was naturally not possible. It was therefore a fundamental decision that was made because VOEST-ALPINE was in a good financial position. The decision to design and build a turning-boring-milling centre was finally made in October 1982. The economic success was not cut and dried and the designers were confronted with internal criticism and scepticism.

The decisive breakthrough finally came with a research project in the East. One of the two main competitors was VOEST-ALPINE. The company had the courage to make an offer covering control technology, transportation technology and machine technology. Even back then, one of the main reasons for accepting VOEST-ALPINE’s tender, was the MILLTURN and the concept of turning and milling in one machine. This was when the first MILLTURN was sold. The project was later repeatedly referred to as the turning point for the further development of the MILLTURN.

The beginnings of WFL

WFL could not have been founded without VOEST-ALPINE. The Rothenberger family from Germany was already active in the machine tool sector at the time and took over WFL after the privatisation of VOEST-ALPINE. Since then, the company has successfully built complete machining centres for a wide range of well-known customers in the aerospace, automotive, engineering and plastics industries.

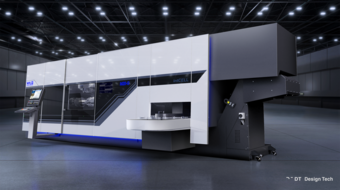

Years of development and research in the areas of technology and machine concepts have enabled WFL to assert itself as a technology leader in the manufacture of complete machining centres. In addition to patented machining technologies, new handling systems have been developed and adapted for an almost unmanned operation of complete machining centres. A look at the current MILLTURNs shows that WFL has surely achieved its goal: complete machining, measuring, loading and unloading of complex workpieces with a minimum of clampings in a single machine.

To the next decades

WFL is one of the world's leading machine tool manufacturers and a pioneer in complete machining. A solid foundation in terms of training and expertise is therefore important. Thanks to more than 30 years of experience and a sophisticated modular machine concept, the multifunctional machines can be perfectly adapted to any requirement and even challenging demands can be mastered.

Automation solutions are a constant companion when purchasing MILLTURN complete machining centres. With the acquisition of FRAI, WFL combines innovation in complete machining with decades of expertise. Automation solutions are particularly in demand to generate growth in smaller machine series and digitalisation requires more and more automation solutions as well.

Thanks to the experience and expertise of its employees, WFL can implement its strategy and continue its development in line with current market requirements.