WFL Prismatic tooling solutions

The decisive advantage

Increase in performance for the turning-boring-milling processes thanks to WFL prismatic tools

WFL develops special tools which are perfectly tailored to the MILLTURN and are used to machine complex workpieces. Hard to access machining area often require long special tools. WFL prismatic tool holders can be used for precisely this kind of challenging machining operation and are secured to the turning-boring-milling unit in addition to the HSK or Capto tool system with a prismatic tool accommodation. These tool solutions enable users to maximise the machine‘s full potential.

Sensors in tools

Integration of ultra-modern sensors enables detailed tool information and machining states to be called up on the controller or tablet. Signals are transmitted via Bluetooth. The machine can respond interactively to a defined trigger event. Suitably equipped tools provide information on utilisation, temperature, deflection, and the surface quality achieved and actively intervene in the machining process in the event of an overload.

1. WFL prismatic tools for internal turning operations

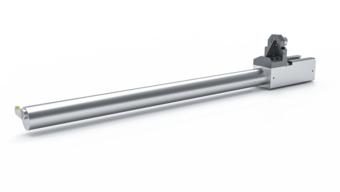

WFL system boring bar

- Optimum stability conditions during tricky internal machining

- Fully automatic tool change on a stable and optionally vibration damped basic boring bar

- The same HSK or Capto tool system as in the turning-boring-milling unit

- Cost-effective variant for use of different cutting heads or use of sister tools during extensive internal machining

Vibration damped, carbide-reinforced boring bars

- Perfect clamping results for optimum machining with maximum boring bar overhang

- Boring bar overhang up to 18xD already achieved

2. WFL prismatic tools for deep hole drilling

- Deep hole drilling: gun drilling, ejector drilling, HTS drilling, etc.

- Perfect drill clamping stability

- Supply option for the right coolant pressure and volume:

- High coolant pressure for small hole diameter

- High coolant flow rate for large hole diameter

- Automatic, quick tool change, either from the tool magazine, pick-up magazine or prismatic tool changer

- Coolant supply via external docking point – either automatic or manual

CNC special contour boring bars

- Production of cavities in deep holes (centric and eccentric): chamber boring, seat pocket, etc.

- Appropriate drive heads for coupling with the optional U-axis

- Use of CNC facing heads

3. WFL prismatic tools for milling operations

- Fully automatic tool change, even for large and heavy tools

- Attachments are mainly made of steel, which means outstanding stability and ability to accommodate high cutting forces

- Individual version for maximum stability and time savings

- Numerous tried-and-tested, industry-specific solutions are available

- WFL standard modular range for optimum flexibility

- The maximum permissible torque can be limited via the WFL controller to protect the attachments