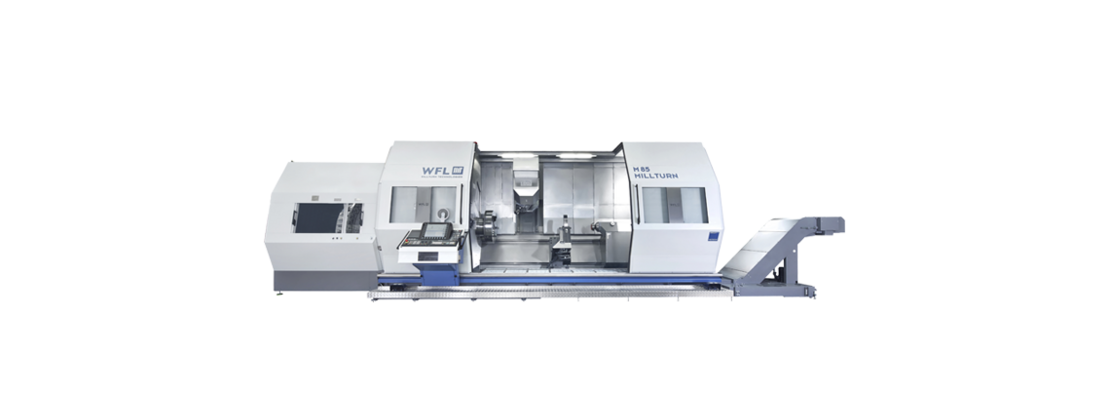

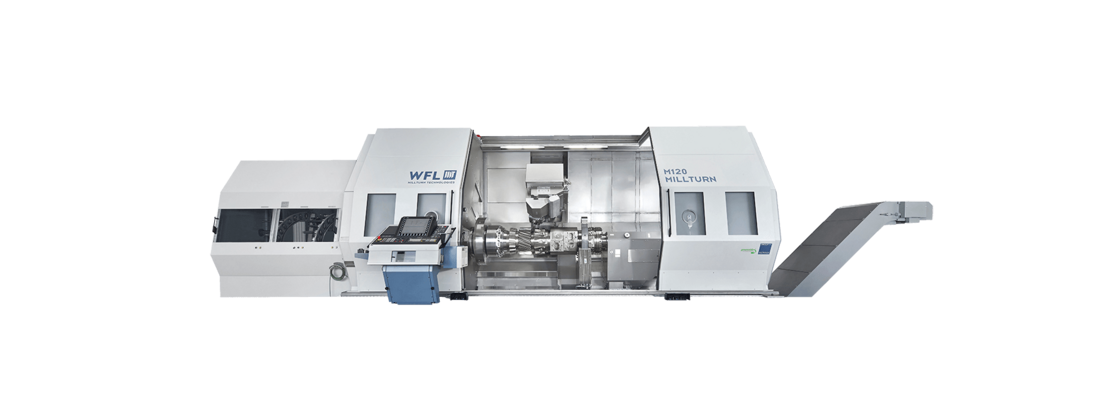

WFL Millturn Technologies GmbH & Co.KG - The technological leader.

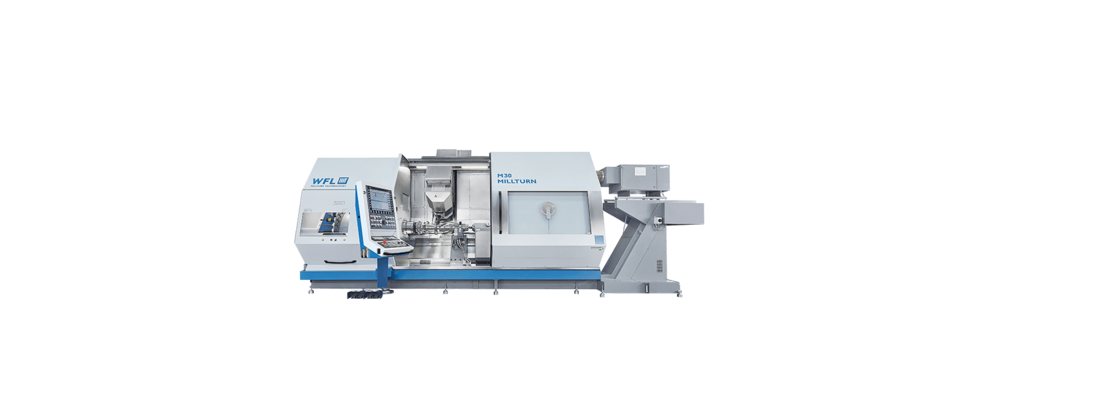

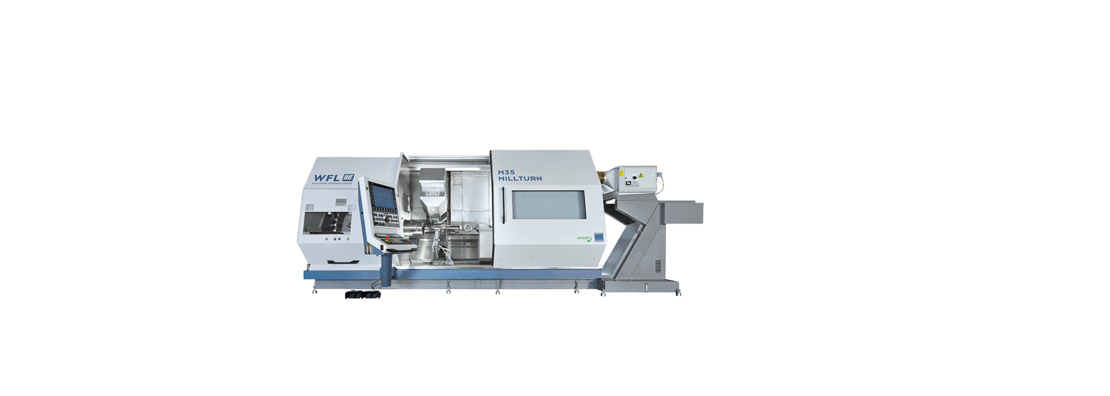

WFL is the only manufacturer worldwide that focuses exclusively on the production of multifunctional turning-boring-milling centers ... more

Global contact partner:

Technologies

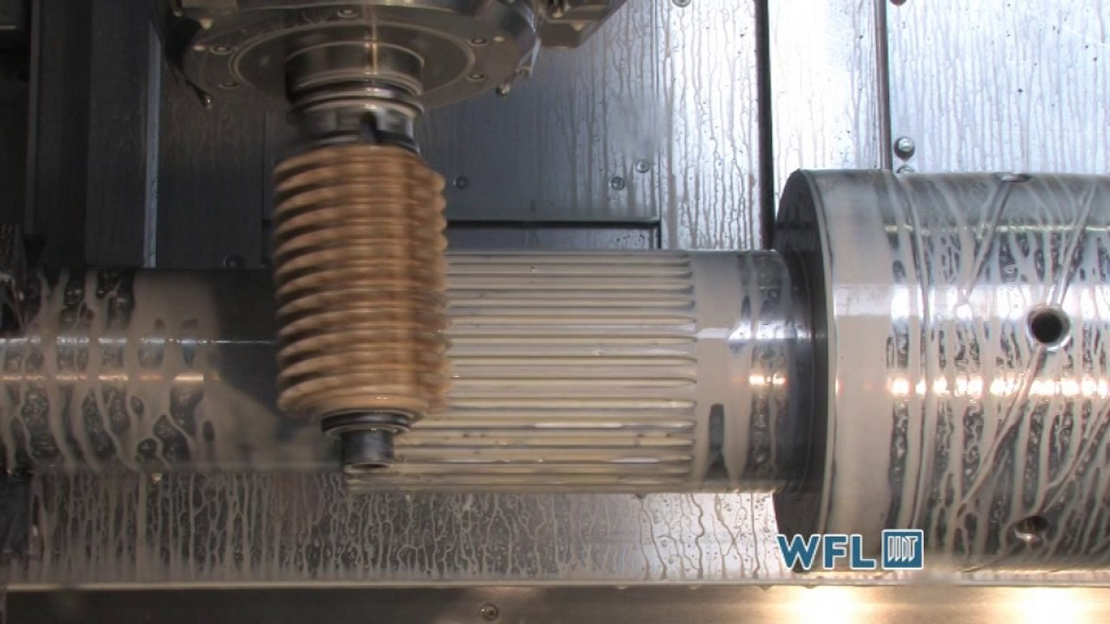

Combining all machining and measuring operations in one single MILLTURN by WFL will raise the efficiency of your production enormously. This is an investment that pays off in virtually no time.

machining result

News

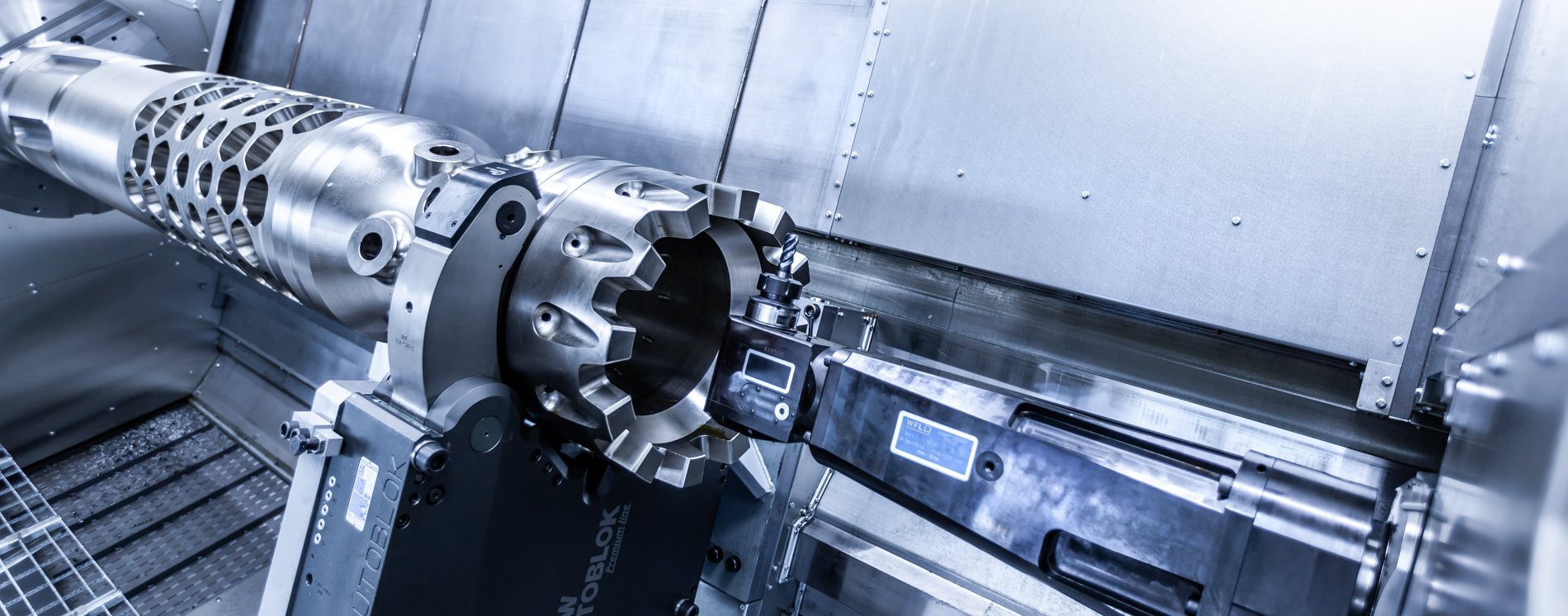

Complete machining of chuck parts

in der Aerospace Industrie

Centring on the core competence of „complete machining“ according to the motto „clamp once – machine complete“, a number of challenges have already been overcome. This also applies to the complete machining of chuck parts in the aviation sector. A MILLTURN completes these complex production tasks to the highest levels of productivity and precision. For chuck parts where the diameters are often the same or considerably bigger than the workpiece length, WFL has been able to gain quite an advantage over the years.

Popular chuck parts include „blades“, „discs“ and „rings“. The latest projects show that chuck parts up to a turning diameter of 1700 mm can be machined on a M175 MILLTURN. With a M175 MILLTURN (Large Swing), it is even possible to machine parts up to a diameter of max. 2000 mm. This means that tremendous dimensions can be machined, all in a single clamping setup.

By using special machining technologies and software tools, it is possible to make machining extremely efficient. For complex chuck parts, an all-round concept is needed which delivers excellent results for the customer. The T-series and TBseries have fared particularly well in this regard. The T40 – T150 series are slant bed turning machines with one or more tool turrets for difficult machining and the high-precision machining of shafts and chuck parts. In addition, the matter of internal turning with long boring bars also becomes a reality. The TB series offers the optimum solution for complex turned parts and for turned parts which require a high tool stock level. The TB40 to TB150 nable high-precision machining of shaft and chuck parts up to 1500 mm in diameter and a workpiece length of max. 8000 mm*.

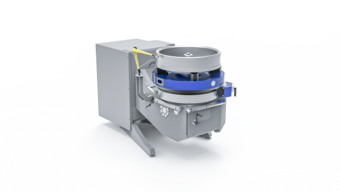

The complete machining of chuck parts is diverse and requires an individual solution to every project. Automation solutions, for example, are the perfect addition for an even more efficient production environment. An automated system with robots or gantries allows chuck parts to be optimally stored and machined in pallet systems.

*Higher values available upon request

Machining example 1:

4-axis complete machining of discs (top/bottom concept) By enabling the workpiece to be machined from the top and bottom and by using two single tool holders, maximum productivity is guaranteed. The top system can hereby be designed as a turningboring( TB) unit, turning with X-, Z-, Y-, B-axis, or as a milling-turning(MT) unit, 5-axis complete machining. The bottom system is then set up as a T unit. Both tools can be exchanged automatically – and above all, very quickly – at any time.

Machining example 2:

4-axis complete machining of rings (top/bottom concept) By using two single-tool holders (top/ top), this variant allows you to achieve a compensation of the cutting forces. For workpieces with thin walls in particular, this produces a significantly better workpiece quality and shorter machining time. The top system in this case is set up as

a TB (turning with X-, Z-, Y-, B-axis) or MT (5-axis complete machining) unit. The bottom system is set up as a T-unit (turning with 2 axes). Both tools can be exchanged automatically and very quickly.

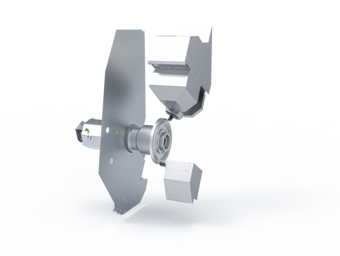

Other features for machining chuck parts – the WFL pallet system for workpiece clamping:

Traditional clamping devices take up a lot of time during clamping and adjusting. The new WFL solution allows quicker, more flexible and, above all, very precise changeovers. The workpieces can be clamped and aligned parallel to machining time into the clamping device on the loading station in front of the machine. The clamping device and workpiece are then exchanged manually, semi-automatically or automatically to the interface on the spindle nose and are clamped automatically. This concept eliminates the need for clamping device setup times in the machine. The major benefit here is the quick and, above all, precise exchange of the equipment.

Advantages:

- Clamp once – machine complete

- Highly efficient 4-axis complete machining of disc-shaped chuck parts

- Compensation of the cutting forces as a result of opposing tools for workpieces with thin walls

- Setting up of equipment and workpieces parallel to machining time

- Quick and precise exchange of the equipment incl. workpiece in the machine

- Production of locating holes with very precise positional tolerance

- Process monitoring

- Manual, semi-automatic or automatic loading

- Adapted coolant supply HPC/UHPC (up to 350 bar)

- Automatic exchange of all tools and measuring probes

- Large magazine capacity for machining heat-resistant super alloys, such as HRSA and titanium materials

- Highest levels of productivity and quality

- Durability

- Automatic run-out and roundness measurement with scanning measuring probe

- Turn-milling instead of turning for uninterrupted cut

- Process design and turnkey solutions by WFL

Worldwide

WFL locations

More than

Excited employees

More than

Registered patents

WFL software, service & support

CrashGuard, the patented collision prevention system is a real-time software extension of the CNC control system.

MORE

CrashGuard Studio, the realistic 3D simulation software is the ideal tool for testing and optimising CNC programs after they have been created or modified.

mORE

We are close to our customers. Major manufacturers put their trust in WFL’s vast experience. A head start that reflects in WFLs services. Please find here our offers.

WFL NEWSFLASH

Register now!

The WFL NEWSFLASH informs you about our latest innovations in complete machining, technological highlights and modern services as well as upcoming events and exhibitions.

Register now and do not miss out on any WFL news!

COMPLETE

The complete machining magazine

Explore tomorrow's world of complete machining. Be inspired by innovative technologies, success stories and product highlights.

Dive into the world of WFLs' complete machining.