WFL Millturn Technologies GmbH & Co.KG - The technological leader.

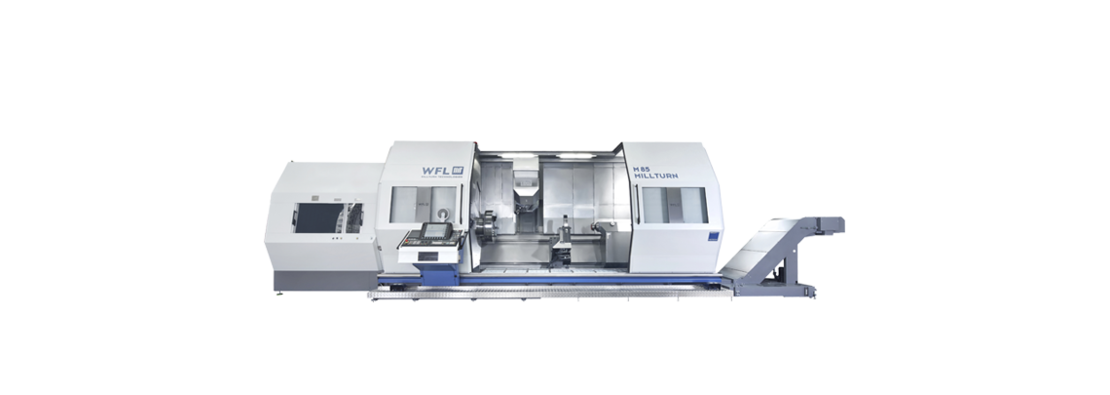

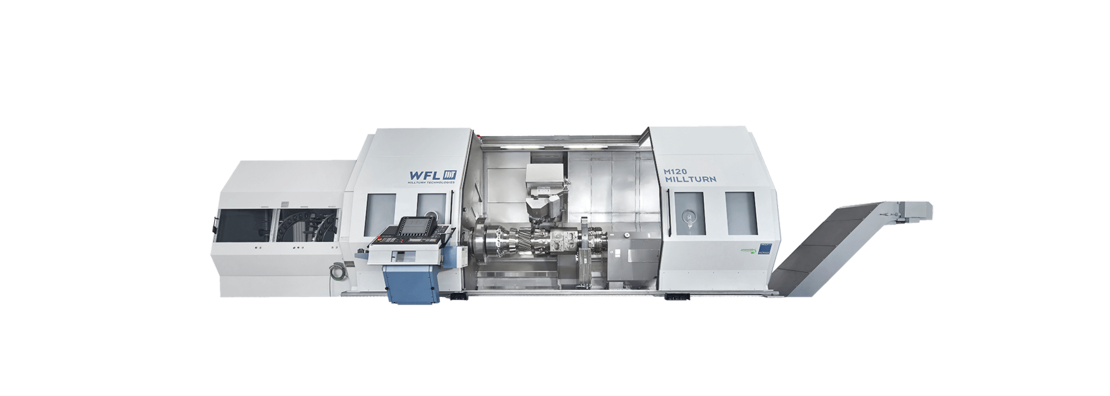

WFL is the only manufacturer worldwide that focuses exclusively on the production of multifunctional turning-boring-milling centers ... more

Global contact partner:

Technologies

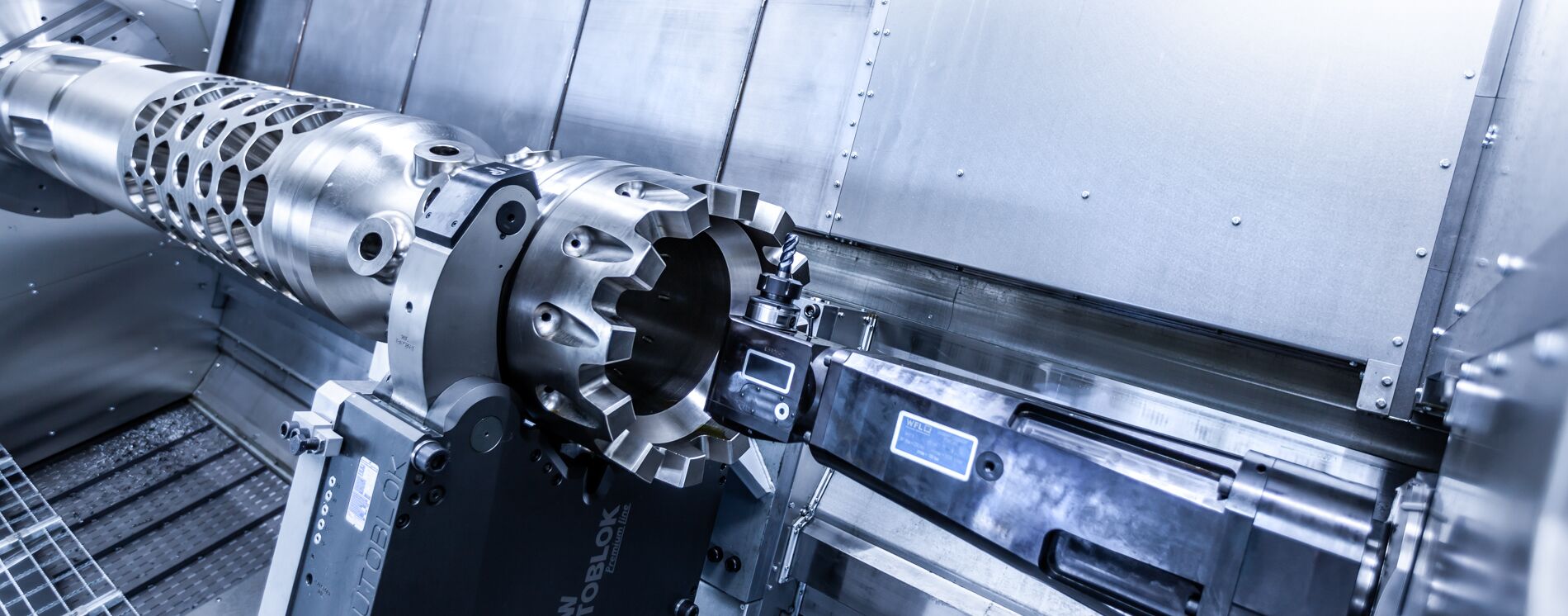

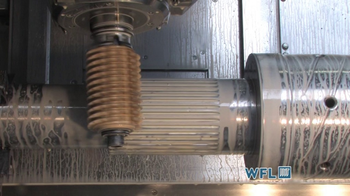

Combining all machining and measuring operations in one single MILLTURN by WFL will raise the efficiency of your production enormously. This is an investment that pays off in virtually no time.

machining result

News

The intellectual and digital craft of creation

The most important upstream processes and elements of mechanical engineering are still the design, construction, configuration and development of innovative technical solutions. In the past, development and design were treated as separate entities. In this day and age, such a traditional distinction is becoming less and less important. Instead, each sector is striving for symbiosis. All ought to profit from one another, thereby carrying out work which is precise and efficient. WFL Millturn Technologies has valuable resources in these areas for solving every constructional problem and simplifying them through brilliant ideas. In this edition of Complete, we would like to introduce the man pulling the strings in the design department. We talk about everyday life at the company and gain a few private insights.Wolfgang Gattermayr – the eminent authority in product design and a teamwork specialist.

Mr Gattermayr, please tell us something about yourself.

First of all thank you for your kind words. I‘m not sure about being the eminent authority though, I think that may be a slight exaggeration! (laughs)

My motto has been and remains achieving our goals together through collaboration and thinking outside the box. The driving force for this is simply enthusiasm, based loosely on a quote from N. V. Peale: „Enthusiasm is the never-flagging impulse that makes us doggedly pursue our goal“. But first let me tell you a bit about my youth: Thanks to my parents, I was blessed with positive genes in many areas. That‘s why I found it very difficult to decide which direction to take in life. Many influences, such as a love for nature, the desire to pursue sporting activities, an enthusiasm for teaching or a passion for music, to name but a few, did not exactly make it easy for me to choose a path in my professional life. My predominant interest in technology was ultimately the deciding factor in my choice of career – everything else became a hobby. Now I‘m 62, have a house and garden and have been happily married to my wife Monika for 39 years. Doing activities together with our two sons, their spouses and our two grandchildren (13 and 16) always brings us wonderful and unforgettable moments.

What path did you have to take to get to where you are now?

After graduating from the HTBLA technical college in Steyr (majoring in automotive engineering, motor construction and mechanical engineering) and completing my military service, I started my professional life on 1 June 1979. My career began as a detail and design engineer in the mechanical engineering department of VÖESTALPINE-AG, in the machine tool sector.

In the following years up until 1985, I was allowed to participate in all developments in mechanical design, beginning with the „stone age of machine tools“ – i.e. the box column drill and centre lathe – through the first NC slant bed turning machines to the fully automatic, unmanned production line (equipped with the world‘s first „complete machining centres“/MILLTURNs).

In 1985, I was entrusted with heading up the mechanical design and order processing department „Production cells and special machines“. It was like jumping in at the deep end, which I dared to do after a short period of consideration. Times were uncertain back then: the machines, the automation (at that time also designed in house) and also all peripheral equipment such as coordinate measuring machines, coolant filter systems, conveyor technology, etc. were technically immature but for the most part prototypes.

In my youthful exuberance at the time, I subsequently took over the project management of many critical orders simultaneously. Successful acceptance of these projects would have been impossible without my, already at that time, excellent team and the interdepartmental and intercompany collaboration. I raise my hat to them! The success was only possible through team spirit and community. Those „apprentice years“ certainly shaped me and I still benefit from those times today.

In January 1994, I accepted the challenge posed by the role as „Head of Design Engineering“ in the then newly founded company WFL Millturn Technologies. From then on, WFL developed into a globally recognised company with a claim to technological leadership in complete machining. Together with my team, we were able to make a difference during the company‘s development.

What is the main activity in your department?

There is no one single main activity really. My team‘s area of responsibility ranges from support during the pre-sales phase (project planning support) to order processing, quality campaign, purchasing, production and installation support as well as documentation creation. Furthermore, we support the dispatch up to the after-sales phase, servicing, and we also deal with the constructive processing of all after-market sales orders. This means, for example, retrofitting and upgrading of used machines. All activities are important, and the processing of customer orders is treated with the highest priority in terms of deadlines.

What would you say are the advantages of the MILLTURN complete machining centres? What do you believe makes the machine stand out? Could you name three characteristics.

Complexity, production security and durability. I believe that these attributes distinguish us and give us that certain edge which we have worked hard for over the years.

What will be the next technical quantum leaps at WFL or for the MILLTURN complete machining centres?

Having worked in the machine tool sector for over 40 years now, I have very high expectations when it comes to quantum leaps. In the past I used to perhaps see this as developing a conventional centre lathe into an NC turning machine, or moving from the NC turning machine to the complete machining centre. While it may be desirable, I believe that there will be no more such fundamentally groundbreaking achievements. Now we are in an era of ongoing improvements made up of smaller steps. In other words, we are on the road towards automation and digitalisation. However, the demand for production machines that conserve energy and resources must also be taken into account.

How does your physical and mental balance offset your stressful daily life?

Having a good balance is crucial! The times when I jumped into my running shoes after a hard day and mentally freed myself on a run are unfortunately long ago as I am not as fit as I used to be. Nevertheless, sporting activities play a very important role. Of course, the all too rare bicycle tours or tennis matches with my active and already retired colleagues have a very relaxing effect. Gardening and music are also soothing counterparts to my action-packed everyday working life.

What has been the most defining experience during your years at WFL?

No matter what you are facing, with solidarity, team spirit, and above all enthusiasm for common goals and selfless action, you can overcome even the worst crises and emerge stronger from them. It is important to pass on this positive way of thinking to our next generation of colleagues. My department is ready for this and nothing now stands in the way of a smooth generational change.

If you could call yourself up for 30 seconds at any time in the past or future, when would you call and what would you say?

Frankly, I would need some time to think about this question. But from a spontaneous point of view, I would call myself at the time after my technical training and say: „Now take a chance!“ My path would then have gone either in the direction of sport or music. Now that I know that everything has gone well in the technology sector, it would be very interesting to see if things would‘ve also worked out if I‘d gone into sport or music. Maybe as a guitarist? Writing songs, captivating the audience and touring the great stages of the world. Or as a footballer? Thrilling an audience of millions in a running duel with the champion wingers and masters of dribbling... yes, that would have been great, too. I certainly wouldn‘t have been at the top of the music charts or at the peak of sporting excellence, but I would definitely have enjoyed it very much.

Thank you for the interview!

Worldwide

WFL locations

More than

Excited employees

More than

Registered patents

WFL software, service & support

CrashGuard, the patented collision prevention system is a real-time software extension of the CNC control system.

MORE

CrashGuard Studio, the realistic 3D simulation software is the ideal tool for testing and optimising CNC programs after they have been created or modified.

mORE

We are close to our customers. Major manufacturers put their trust in WFL’s vast experience. A head start that reflects in WFLs services. Please find here our offers.

WFL NEWSFLASH

Register now!

The WFL NEWSFLASH informs you about our latest innovations in complete machining, technological highlights and modern services as well as upcoming events and exhibitions.

Register now and do not miss out on any WFL news!

COMPLETE

The complete machining magazine

Explore tomorrow's world of complete machining. Be inspired by innovative technologies, success stories and product highlights.

Dive into the world of WFLs' complete machining.